Plastic Machining

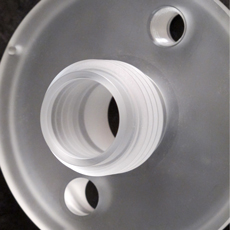

It would be an understatement to say that the applications for plastic are widespread. With that in mind, the prevalence of plastics in virtually every industry means that providers of plastic machining must truly stand out to remain competitive—and Machine Incorporated does just that.

An industry leader in plastic machining

An industry leader in plastic machining

We’ve been able to remain an industry leader when it comes to plastic machining because of our commitment to constantly offering better plastic machining characterized by superior quality, efficiency, and greater value to our customers.

At Machine Incorporated, we use our expertise to deliver every benefit that plastic machining has to offer. Providers of precision machining often approach plastic machining as if it was metal, and that’s where we draw our first distinction.

Plastic machining can be an excellent alternative to metal machining. It allows for light weight, flexible, and corrosion resistant parts and components. However, plastic is not metal. Plastic machining requires a specific approach to design and engineering that takes into consideration unique work holding and tooling requirements in order to achieve the proper surface finishes and close tolerances.

We frequently employ plastic machining techniques such as:

- Deburring: Machine burrs are a natural byproduct of the plastic machining process that must be removed without affecting the geometry or surface finish of the part. Our highly effective deburring process ensures the overall cost efficiency of the machining process and the integrity of the machined plastic part.

- Finishing for plastic machining: Finishing for plastic machined parts requires very specific tool geometries to achieve optimum machining speeds, and the plastic machining services at Machine Incorporated have been honed to strike the perfect balance.

- Fixturing/Workholding: When plastic machining, plastics need to be fixture carefully so as to not stress the material. We’ve developed an extremely successful system for fixturing materials before plastic machining begins to ensure that residual stress is eliminated.

- Hardware inserts: Plastic machined parts often incorporate thread inserts, which help plastic parts achieve greater thread strength.

- Stress relieving: Stress relieving before plastic machining is often done prior to the production process to enable our experts to produce the required close tolerances with plastic machining.

Plastics are literally just about everywhere. They’re in the products we use every day, the machines we rely on, and modern plastics with their light weight and resistance to corrosion are even beginning to substitute metals for parts in the aerospace and automobile industries. Industries we provide plastic machining for include:

- Plastic machining for fluid control

- Plastic machining for heavy equipment

- Plastic machining for medical instruments

- Plastic machining for the telecommunications industry

- Plastic machining for diagnostic equipment

- Plastic machining for electromechanical assemblies

- Plastic machining for the aerospace industry

- Plastic machining for the automobile industry

- Plastic machining for the medical industry

- Plastic machining for the military and department of defense

- And many more industries and markets

- ABS

- Acetal Copolymer

- Acetal Homopolymer

- Acrylic

- CPVC

- Delrin 150

- Delrin AF

- Ertalyte

- G10

- HDPE

- Hydex

- Noryl

- Nylatron

- Nylon

- Nylon MD

- Nylon Type 6

- Nylon Type 6/6

- Peek

- Polycarbonate

- Polyimide

- Polypropylene

- Polysulfone

- Rexolite

- Techtron

- Teflon PTFE

- Tivar HOT

- Torlon

- ULtem

- UMHW

- Vespel