About Machine Incorporated

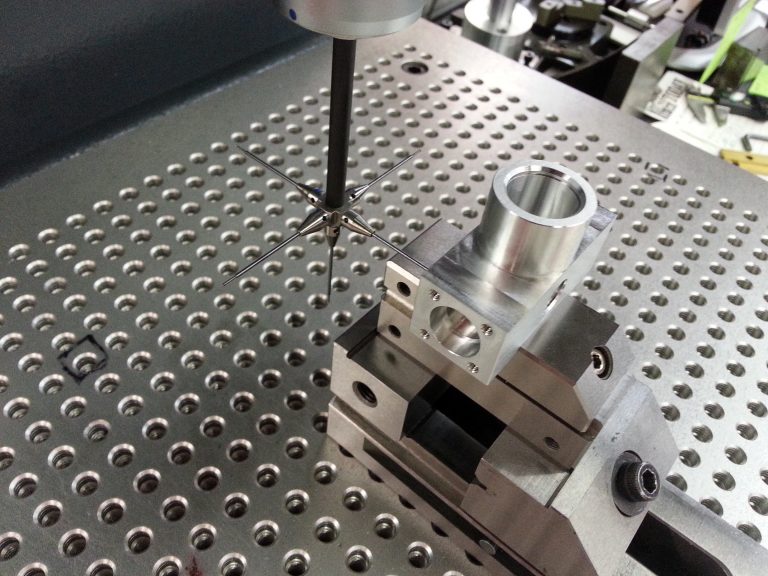

Machine Incorporated is a ISO 9001:2015 and AS9100D Certified and highly reliable Precision Aerospace Manufacturing Company in Massachusetts.

We are a preeminent supplier with FAA-PMA approvals, and dependable in both product and customer service. As a precision aerospace manufacturing company in Massachusetts, we aim to meet all your aerospace needs.

With a commonsense approach to business and defined, stable processes in place, Machine Incorporated has maintained a high standard of quality, consistency, and cost effectiveness since 1981.

Our cost-effective approach incorporates lean practices that translate across the board. As a result, you will know you are getting competitive pricing while maintaining the integrity of the quality and precision of your parts.

Our Promise of Dependability Includes:

- Providing expert technical advice on component design, manufacturing processes, and inventory management

- Combining competitive pricing and top-quality standards

- Helping you improve efficiency and manufacturability

- Meeting all your needs to precise specifications

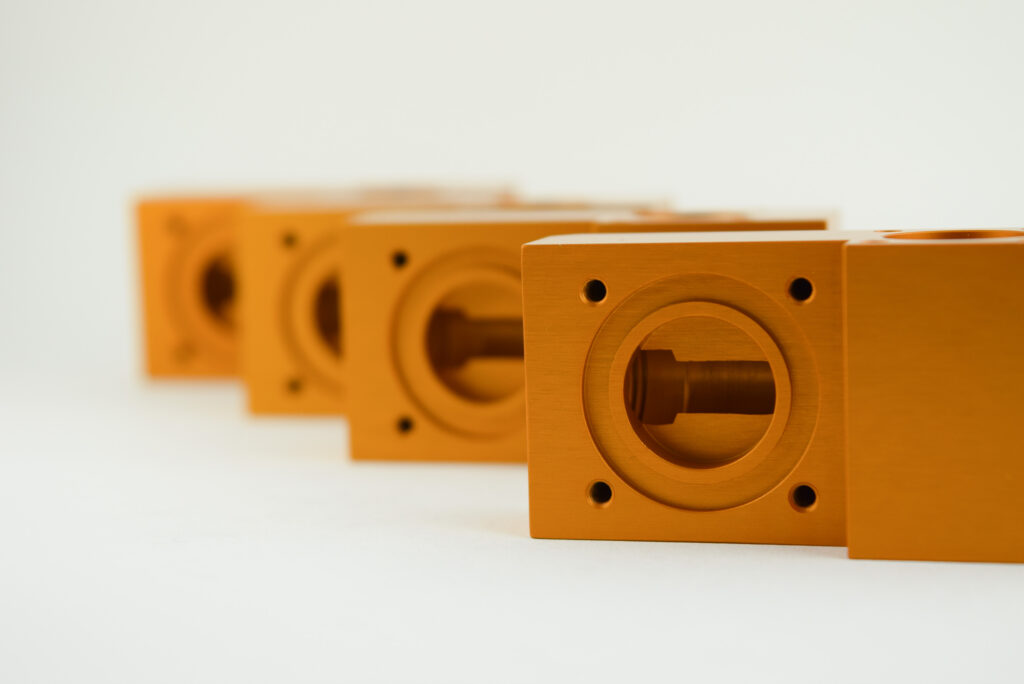

- Producing flawless parts

- Delivering on time

Why Choose Machine Inc.?

Experience. Since 1981, Machine Incorporated has built a reputation as a dependable source for machined parts of the highest quality. Because of this, we aim to form steady, long-term client relationships so that we can be closely integrated into your supply chain. The result is to gain insight into your schedule and respond to changing product demands quickly and proactively.

Dependability. Delivering machined parts of the highest quality when you need them. To support this, we utilize a comprehensive production management software we have the capability to continually monitor and adjust production schedules. Consequently, when we commit to a customer’s stringent delivery schedule we achieve our delivery commitments.

Flexibility. Because all of our employees are cross trained and work in a real-time production management system that provides data and business intelligence, we can respond to your changing product demands quickly and proactively.

Responsiveness. We continually provide you with data and information about your order. Our Quality Department becomes an extension of your Quality Engineer’s specifications and standards. Each week we go over your Open Order Report to ensure that your up to date on deliveries, purchase orders, rejects, Kanban releases and potential problems.

Cost Savings, Inventory Control. Besides employing Kanban systems, we are one of the few firms in our space to use Ultriva for optimizing and automating our clients’ inventory-control processes. Therefore, you can reduce your inventory with the assurance that your parts will be there when you need them.

Expertise. We help you improve efficiency and manufacturability by providing expert technical advice (DFM) on component design, manufacturing processes, inventory management and more. Our state of the art software, equipment and adherence to strict manufacturing, verification and documentation standards ensure parts are flawless, are produced on time and meet all your specifications.

Quality. In a machining environment, quality means fewer customer rejects which translates to lower costs, on-time deliveries and increased customer satisfaction. Process improvements also eliminate waste, improve flow and enhance workplace safety, all contributing to the bottom line given these points.

Cloud-based Inventory Management

Machine Incorporated ensures parts are produced on time, and meet precise specifications and requirements. We use cloud-based inventory management for optimizing and automating clients’ inventory control processes. Vigilant process management allows Machine Incorporated to anticipate customer needs and provide streamlined, proactive results consistently.

Did you know? We also have our own product:

Aviation Quality LED Task Lighting

Machine Incorporated manufactures our own product line of superior quality LED precision lighting for aircraft interior lighting. The products are made and assembled in the United States in our facility in Stoughton, MA. The products meet applicable requirements for use in aerospace and aircraft applications in certified and experimental markets.

Machine Inc. serves the following industries:

- U.S. aerospace and defense industry: Specialized products and services for the Manufacturing segments specializing in commercial aviation and combat systems.

- Analytical instruments and laboratory equipment for Universities, Environmental Protection, Medical and Veterinary applications.

- Medical Equipment Industry producing components for companies specializing in arthroscopy, dental, endoscopy, laparoscopy, spinal, veterinary and MRI.

- Electro-hydraulic actuators and drives used in multiple industries including power generation, oil and gas transmission, water treatment and mining.

At Machine Incorporated, we take pride in our history of reliability and business integrity, having built relationships with many long-term customers who appreciate our commitment to exceptional service and delivery. Our commonsense philosophy extends beyond typical business practices and keeps common courtesy, consistency, and fairness at the forefront-right where you, our customers, are. Find out what doing business with a highly reliable aerospace machining contract manufacturer is like.