With industry leading capabilities, lean manufacturing, and concurrent engineering, Machine Inc. has optimized Multi-Axis Machining equipment to offer a level of comprehensive quality that’s a step above the rest.

What is Multi-Axis Machining? Multi-Axis machines allow for a done-in-one approach. These machines employ more than one area for holding workpieces, and more than one area for holding tooling. This enables us to:

- Deploy autonomous, full-time quality control that’s focused solely on inspection

- Provide DFM (design for manufacturability) feedback to the customer

- Utilize multiple turrets to work on two sides of a part simultaneously

- Maintain SPC (statistical process control) to monitor quality

- Activate live tools to enable part finishing on one machine

- Closely hold tolerances within “tenths” range

- Support universal CAD and Solids Files And more

All of which translates into lower component cost to the customer.

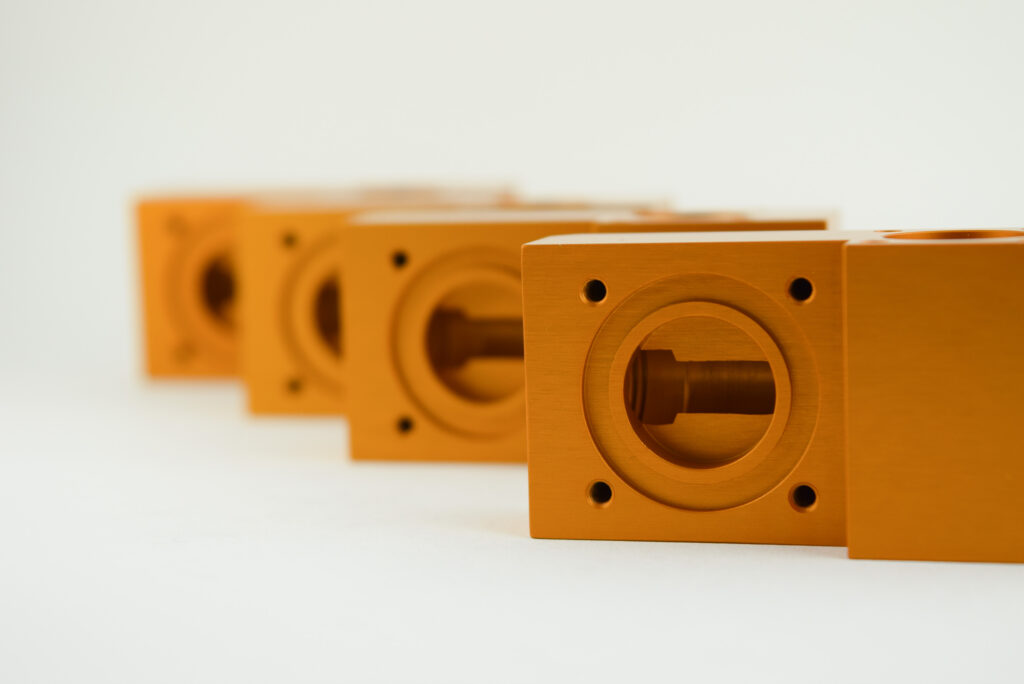

Multi-axis turning applications may include sleeves, housings, valve components, and pump components. It could also be a cost-saving approach for couplings, manifolds, or nozzles and other fittings.

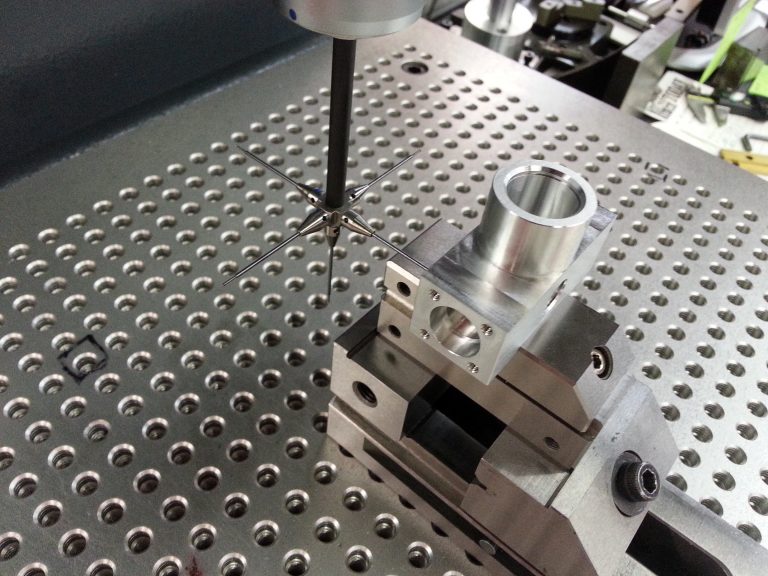

Swiss-Type Machining

CNC Swiss machining is frequently used for machining products out of hard materials with exceptionally tight tolerances within millionths of an inch. While Swiss machined parts are often small precision parts, they can also be larger parts such as in the case of an axle. Regardless of part size, Swiss machining is focused on producing parts and components that flawlessly meet specifications. We have had the opportunity to provide Swiss screw machining for industries such as the aerospace, military, and medical industries. Some sample applications for Swiss machined parts, products, and components include:

- Aerospace

- Defense

- Diagnostic equipment

- Fluid Control

- Heavy equipment

- Medical instruments

- Motion Control

- Power

- Telecommunications

Components that flawlessly meet specifications

We constantly work with industries where extremely stringent quality specifications are an absolute must. By combining our ability to deliver machining close tolerance in the 40 to 50 millionth range with advanced quality controls and a firm dedication to lean manufacturing, our CNC Swiss machining services have met the needs for some of the most exacting requirements. This commitment to quality has helped us develop a significantly strong reputation for our ability to provide Swiss machining for medical components and other small precision parts.

By using concurrent engineering and exhaustive quality inspection, our machinists and inspectors ensure that every CNC Swiss machining project can be completed as effectively and efficiently as possible—increasing part quality, decreasing production cost, and reducing lead times. Regardless of size or specification, our Swiss machining services provide a worry-free solution for precision Swiss machined parts and components that meet every quality and performance requirement.

For more on how we can provide multi-axis CNC

turning for your precision component needs, don’t hesitate to contact us to communicate with one of our experts.

Learn more about…