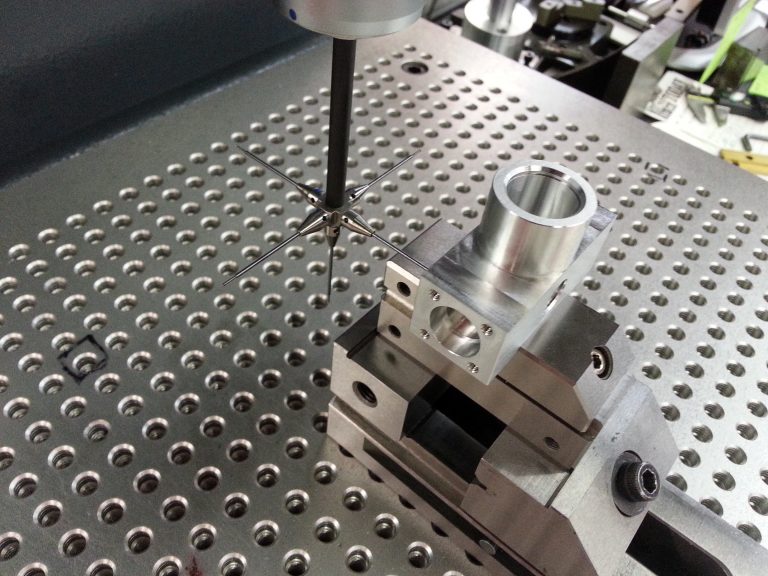

As part of our strategy to maintain high standards and consistency in scheduling, production, and delivery, Machine Inc. uses multi-palleted CNC milling machines.

How does this investment in high-quality, multi-palleted tooling machine centers help us provide superior, consistent quality and keep delivery on schedule? Multi-pallet machines allow for tooling to remain in place between runs. This enables us to:

- Save time and resources, not having to breakdown and setup machines for every job

- Preserve the settings on each pallet, ensuring consistency in tolerances and quality

- Keep deliveries on time-with consistent quality standards intact, delivery schedules remain as promised

- Have quick-turn production runs if Kanban releases get accelerated

- Run a variety of jobs at once, horizontal and vertical machines are able to handle many configurations simultaneously

- Handle larger quantities and types of projects Be flexible with Kanban release dates

All of which translates into lower component cost to the customer.

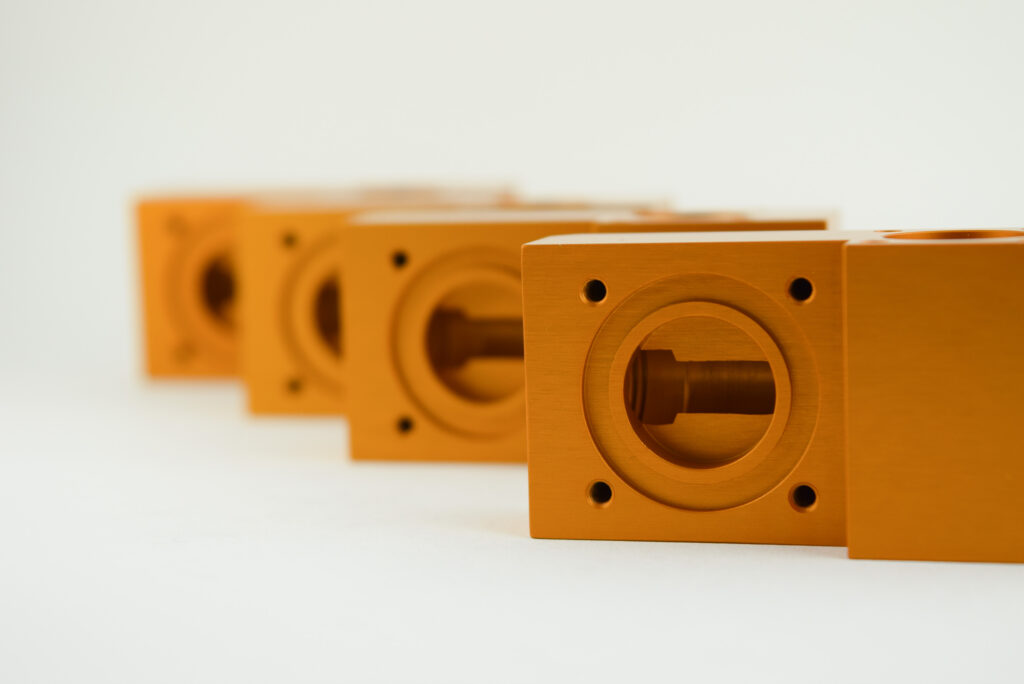

From the earliest stages of your project through completion, our highly skilled technicians at Machine Inc. will offer their expertise to ensure your components are precisely what you need. This includes everything from design assistance to ensure low-cost manufacturability, to material selection, prototyping, protective finish selection, final assembly, and more.

For more on how we can provide the CNC machining for your precision component needs, don’t hesitate to contact us to communicate with one of our experts.

Learn more about…