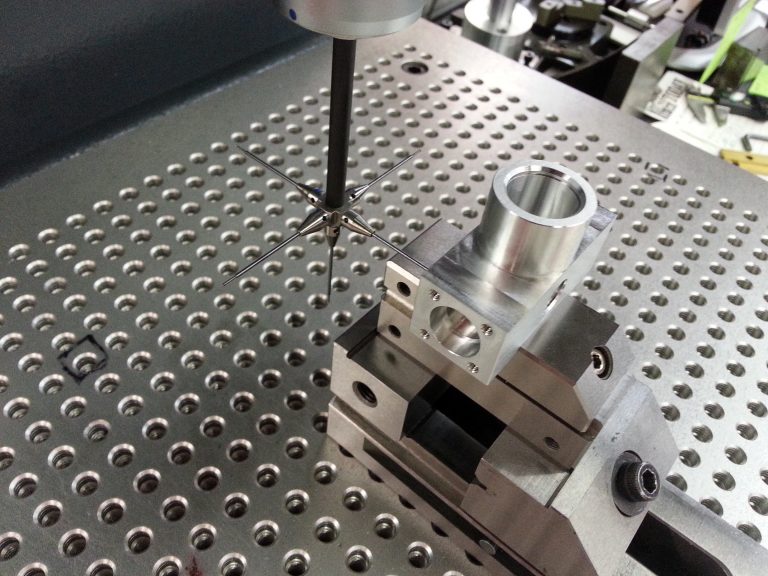

Precision Aerospace Machining

Since 1981, Machine Incorporated has built a reputation as a dependable source of on-demand aerospace machine parts of the highest quality.

Our commitment to honesty, integrity, versatility, and commonsense procedures have earned us excellent quality and delivery ratings and long-term, trusted relationships.

Turn to Machine Inc for Precision CNC Aerospace Machining AS9100 located in Massachusetts.

Precision Aerospace Machining AS9100

Component-Specific Areas of Expertise:

Precision Aerospace Machining AS9100

Our Other Areas of Expertise:

Precision Aerospace Machining AS9100

Our Quality Management System:

Our Approvals:

Our Community:

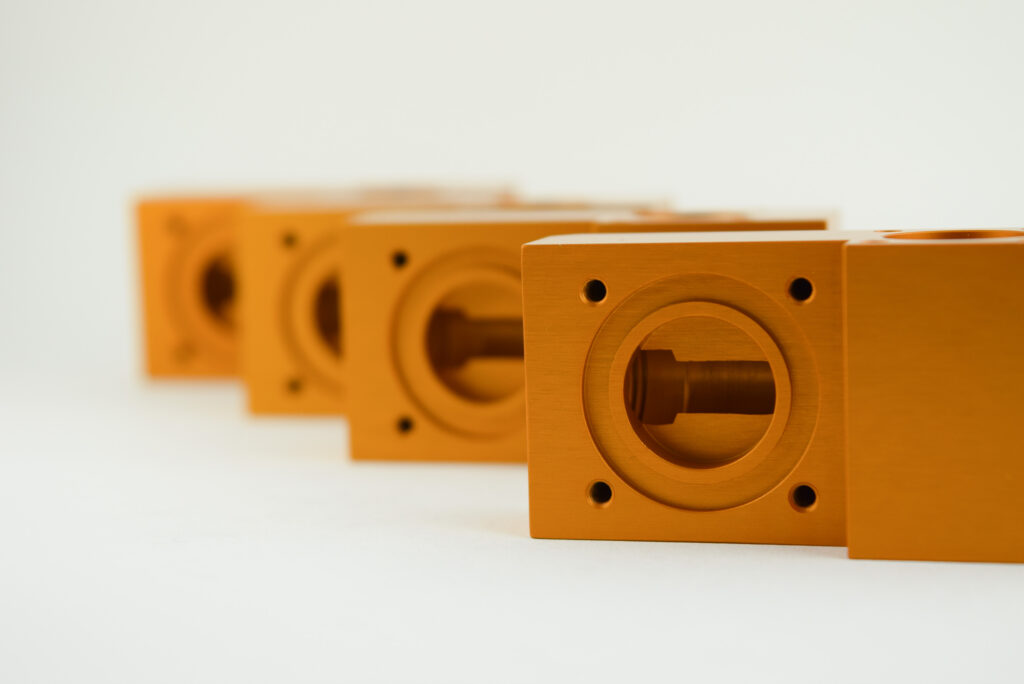

Varied Materials

We work regularly with Aluminum, Stainless, Red Metal, Alloy Steel, and Plastic

Precision Aerospace Machining AS9100