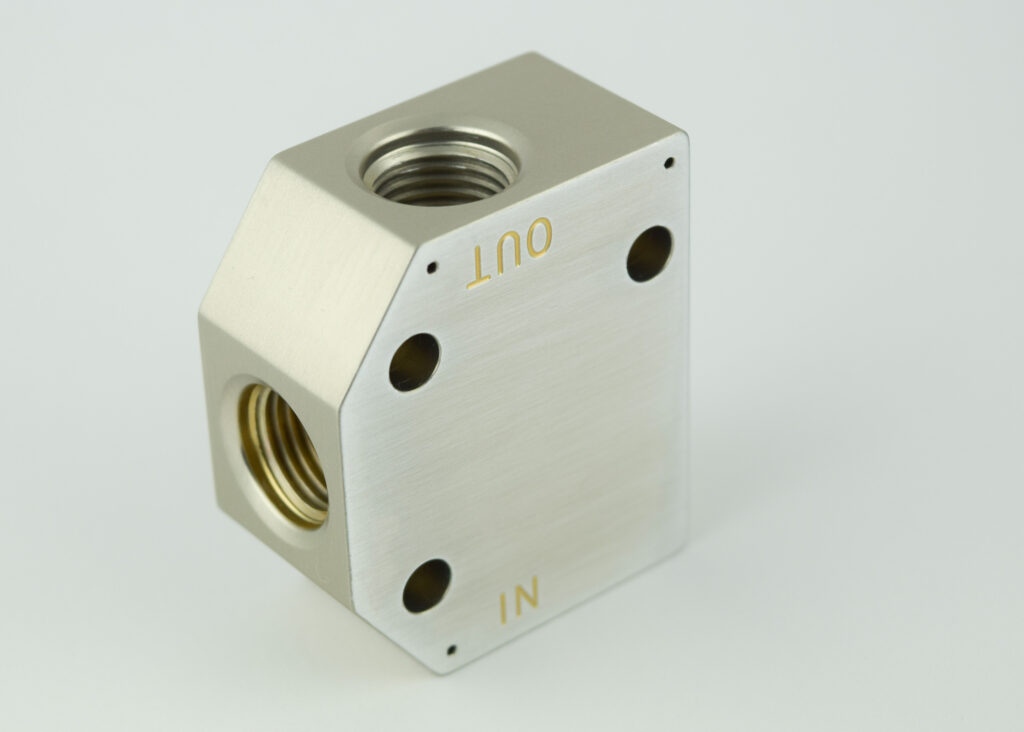

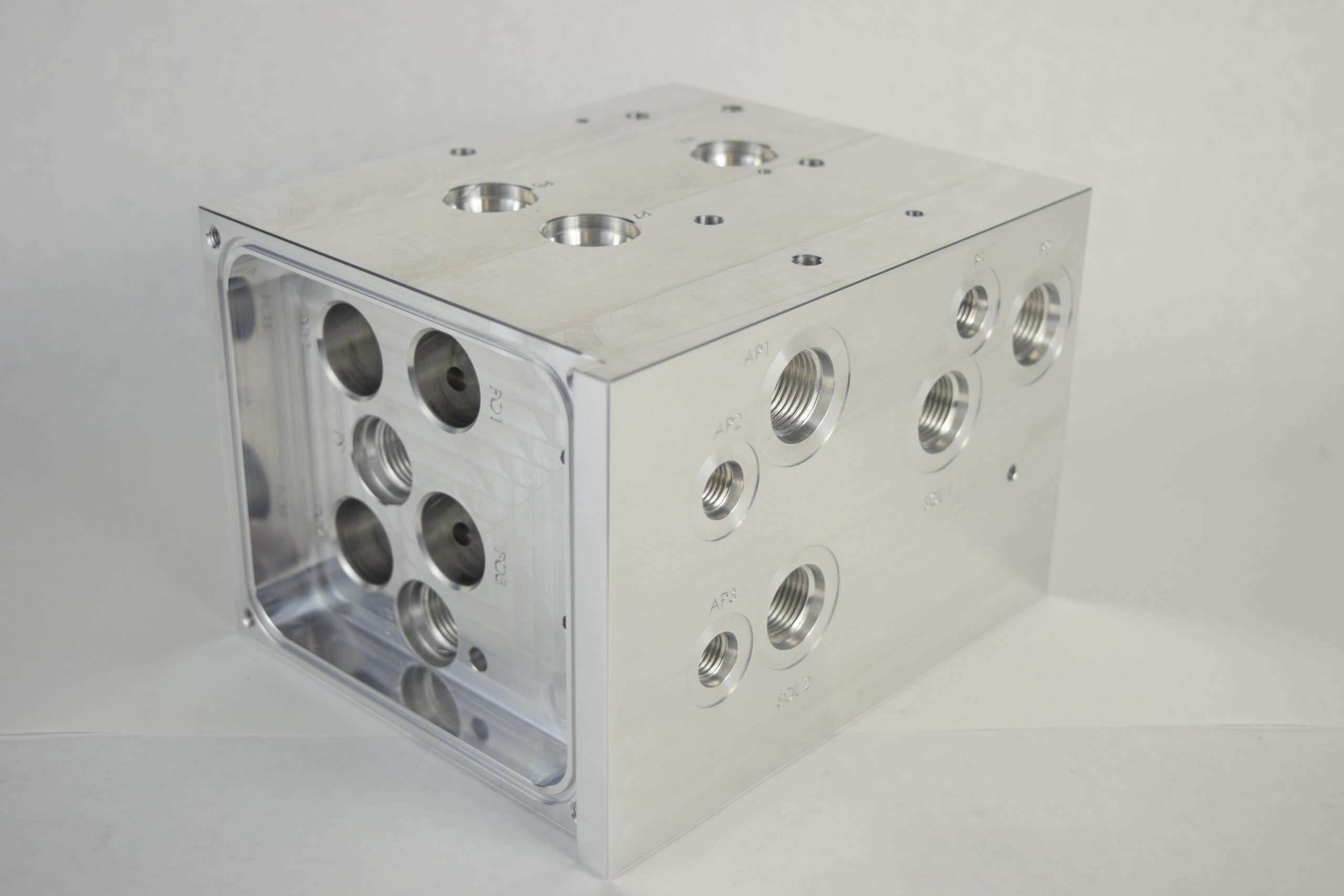

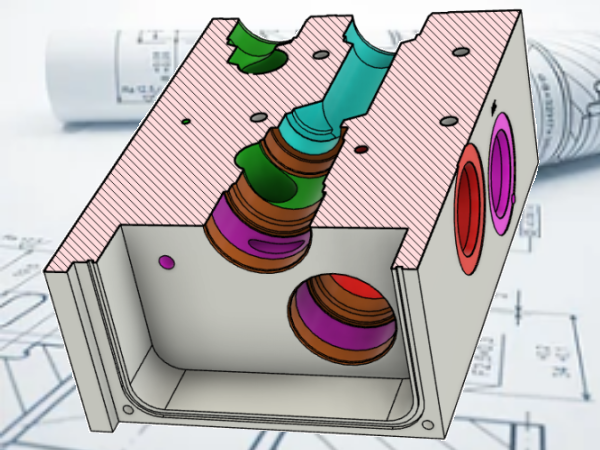

The word manifold means “consisting of many” and manifolds are most frequently thought of as a single circuit block with many openings that are all connected. Manifolds can be manufactured in common and exotic metals and plastics.

Machine Incorporated produces a wide variety of manifolds for virtually any industry that needs them.

We understand the need for reliable manifolds and approach every project with the goal of providing manifolds that deliver precisely the performance needed for the given function.

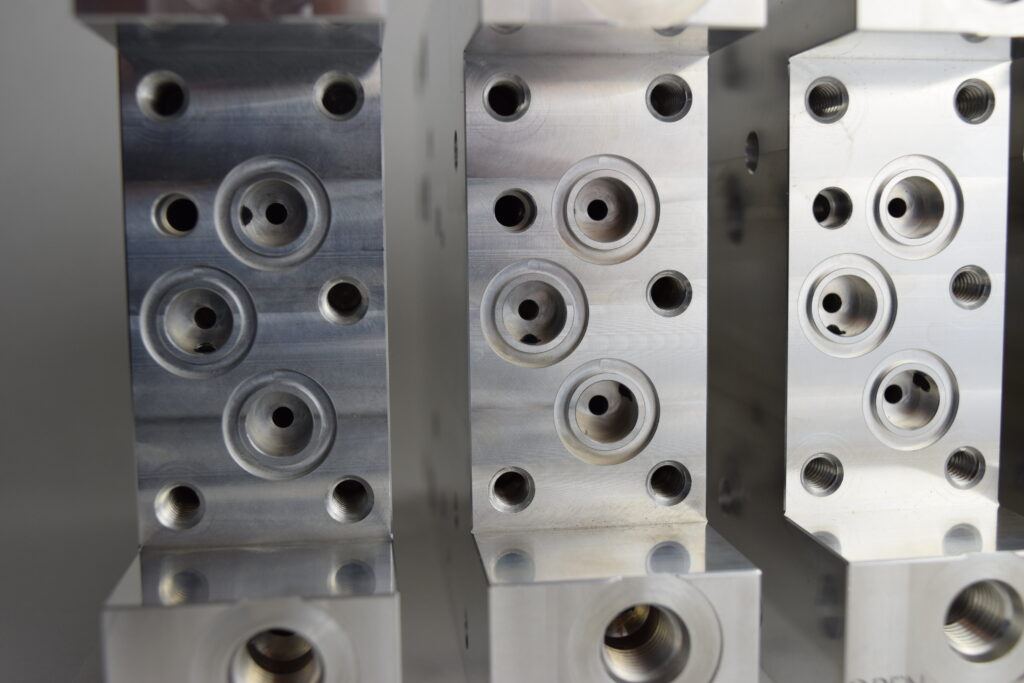

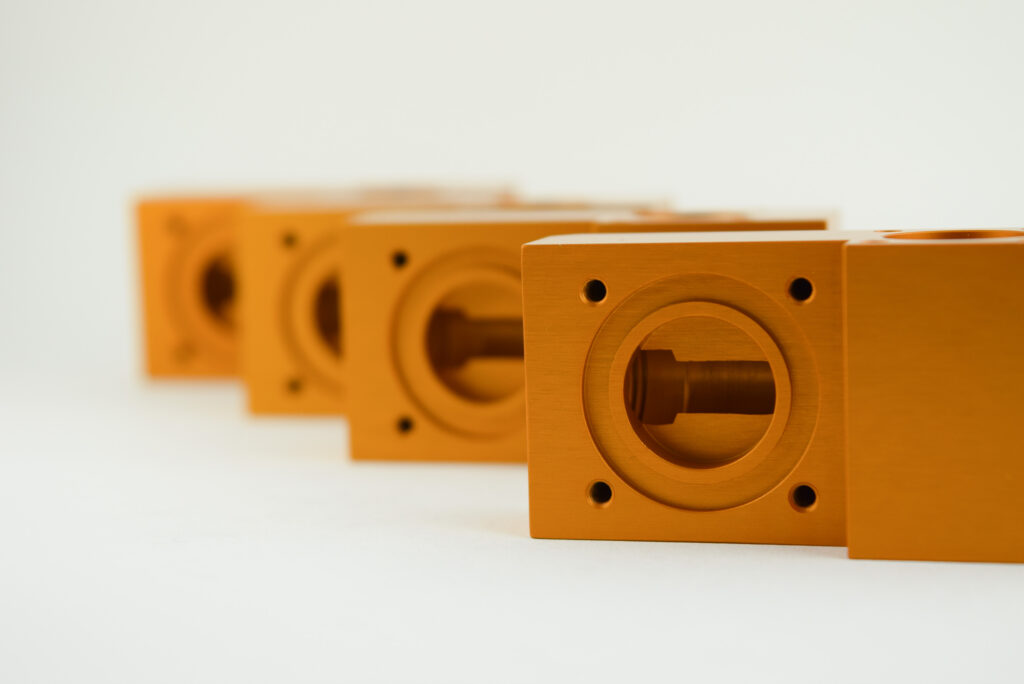

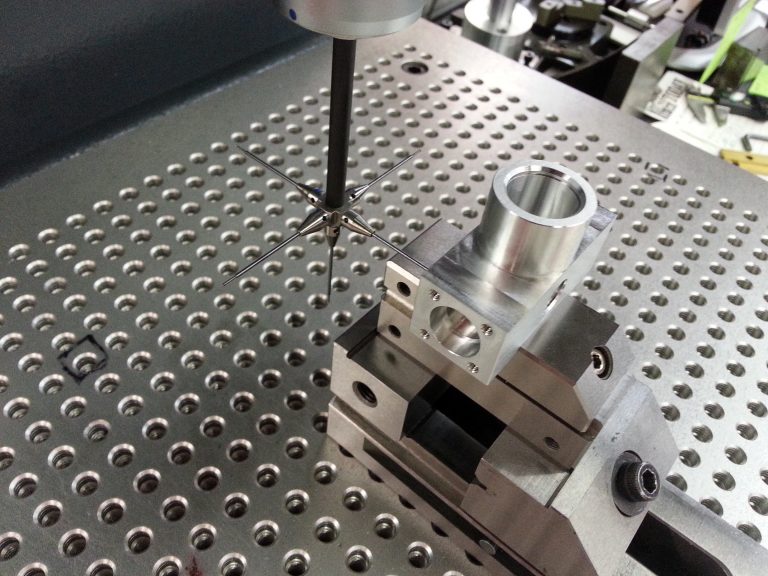

CNC milling for manifolds is one area where Machine Inc. leverages our experience to provide high quality results, low production costs, and fast delivery. Through a combination of expert design analysis, material selection assistance, and machining expertise, we can provide manifolds for even the most complex applications.

High quality results, low production costs, and fast delivery

Our advanced CNC milling capabilities, full assembly services, and approved outside process monitoring allow us to provide full-service machining for manifolds intended for a variety of applications. These sometimes include:

- Manifolds for pressure control valves

- Manifolds for diagnostic equipment

- Medical equipment manifolds

- Fuel management manifolds

- Thermal control manifolds

- Manifolds for heat sinks

- Aerospace manifolds

- Manifolds for pumps

Specialized Components

At Machine Incorporated, we have a great deal of experience working with engineers and designers providing manufacturability input on new designs to optimize cost savings when the product moves to the production stage. From prototypes to finished products including connectors, pump and valve components, housings, instruments, and optics. Our unique set-up methods and manufacturability expertise allows us to give you valuable design feedback during this critical step in launching a new design. We are equipped to accept virtually all CAD and Solids files, produce prototypes then follow through to production seamlessly.

Machine Inc. can help you analyze your manifold design possibilities and provide valuable feedback.

Through lean manufacturing and concurrent engineering, we optimize every aspect of the manufacturing process to maximize throughput and provide a better end product. In our business, staying under budget is essential. That’s why we use our expertise to offer design and material selection assistance to avoid wasting money on overdesigned manifolds and other parts.

Delivering a full-service solution

At Machine Inc, we pride ourselves on being able to deliver a full-service solution. Whether that means developing every part of your manifold in-house, coordinating with another supplier, or receiving parts from a number of sources, we can make it happen.

From CNC milling for manifolds to full production and assembly, our customers get the manifolds they need—with the right specifications. Manifolds may typically require surface finishes with a low Ra value, and may require threaded connections to be machined per specifications such as MS 16142, SAE J1926, SAE J514, MS33649, MS33514, AND 10050, and ISO-6149-1, or they may need to be machined brand-specific such as Sun Hydraulics or Wandfluh Cartridge types. We can handle it all. Our capabilities allow us to manufacture and provide CNC milling for manifolds in a number of materials. Some of these include:

- Manifolds in aircraft alloys

- PVC machined manifolds

- Stainless steel manifolds

- Aluminum manifolds

- Ultem manifolds

- Peek manifolds

At Machine Incorporated, our focus can be boiled down to one thing: quality. That means you can expect not only the highest quality machined manifolds, but a high quality of service as well – meaning faster delivery, lower production costs, and exceptional engineering and design assistance.

For more on how we can provide the CNC machining for the Manifolds you need, don’t hesitate to contact us to speak with one of our experts.

Learn more about…