Your engineers know what they want, we know how to work with them. Machine Inc. has a systematic approach that combines engineering and design for manufacturability to maximize quality and efficiency while minimizing production cost and lead time.

Our experts are with you throughout the entire process.

Collaboration

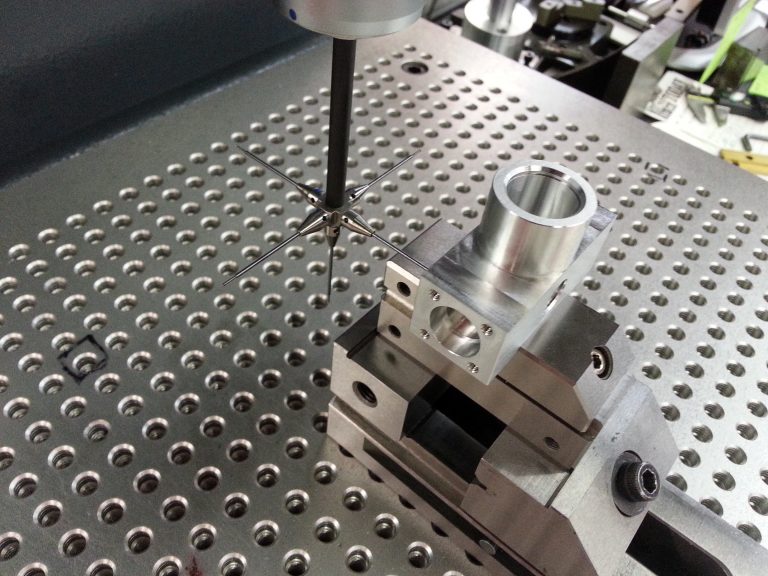

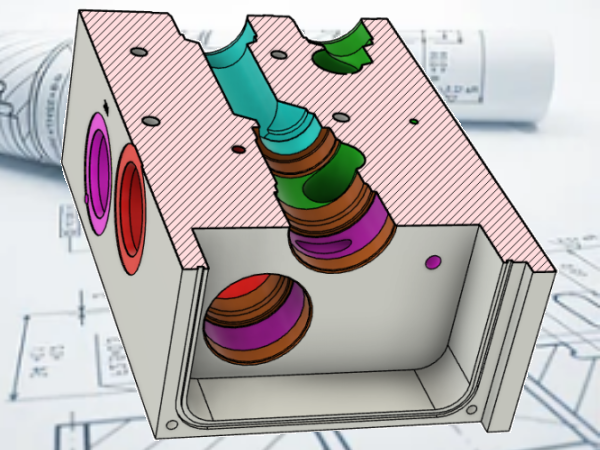

From the very beginning of the production process, our experts at Machine Inc. collaborate internally and with customers to consider every aspect of each process for design, engineering, and manufacturing. Machine Inc. experts have years of experience collaborating with engineers and designers to provide input on the manufacturability of new designs before they reach the production stage. Using this proven experience and the latest CAD/CAM software, Machine Inc. identifies opportunities for design optimization that can help customers cut costs significantly.

Functionality and Manufacturability

The design processes for engineers often takes into consideration the functionality of the final product, while focusing less on manufacturability. Concurrent engineering at Machine Inc. allows us to approach our customers and say, “You’ve designed it this way—but you’d get the same results and spend less if we could do it this way instead.” We will look at tolerances and material selection so each piece is designed with the specifications that work best. And we’ll ask the questions so we can design, produce, and deliver a component with optimal cost reduction and function. Our design assistance for manufacturability can provide you with valuable changes that can reduce the cost of the part, while never sacrificing functionality or performance.

When you need machining for virtually any part, you’re concerned with quality, cost, and a reasonable lead time. At Machine Inc., we’re concerned with the very same things. We’ve optimized every aspect of our business to offer you a service with an inherent value that’s hard to find in this industry. Machine Inc. is the CNC machining supplier that will help you cut costs and get your parts faster. We’re happy to talk to you about your next job.

Concurrent Engineering and Design for Manufacturability Benefits

Reduced Production Costs

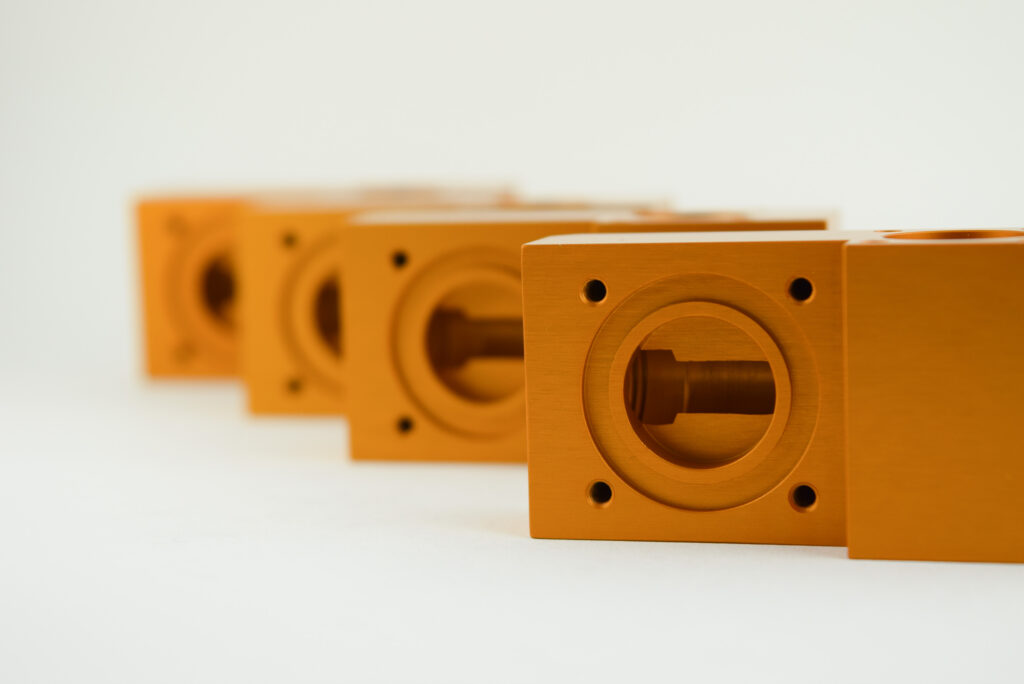

With informed communication, costly design and manufacturing changes late in the process are avoided—reducing production costs and decreasing time to market. Additionally, by taking advantage of design assistance, customers can depend on Machine Inc. to offer direction about which materials to use on each job; this is particularly advantageous when we can forgo costly material if a less expensive material would work just as well. For example, many times we receive original designs calling for a certain stainless steel. In some cases, we can suggest a stainless steel alloy for optimal machinability that will meet the engineering design criteria and reduce machining cost.

Reduced Lead Times

With more efficient collaboration overseeing all aspects of the process and by designing for more effective manufacturability, parts, products, and components, each job can be completed significantly faster than if each stage of the process was undertaken independently. This means that products get to market faster and help contribute to our customer’s bottom line sooner.

Faster Workflow

Concurrent engineering and design for manufacturability enable a higher level of project planning that allows for more effective and comprehensive collaboration, creating a faster workflow. By considering the many aspects of a project in a parallel instead of a linear mindset, we can guarantee that concurrent engineering and design for manufacturability get our customers the parts they need faster. The less amount of time a component spends in manufacturing, the lower the unit cost will be.

Our experts will give you a complimentary Design for Manufacturability Consultation regarding the scope of your job. Contact us today.

Learn more about…