How a Mechanical Parts Buyer Uses Capacity and Lead Time to Choose the Right Machine Shop

In the world of manufacturing, time is money—and precision is everything. For mechanical parts buyers, selecting the right machine shop isn’t just about price; it’s about reliability, speed, and the ability to meet demand without compromising quality. Two critical metrics that guide this decision are shop capacity and lead time.

Let’s break down how these factors influence the decision-making process and how savvy buyers use them to their advantage.

Understanding Shop Capacity

Shop capacity is the backbone of a machine shop’s ability to deliver on time and at scale. It refers to the maximum volume of work a shop can handle within a specific time frame without compromising quality or efficiency. For a mechanical parts buyer, understanding a shop’s true capacity is essential to avoid production delays, missed deadlines, or quality issues.

Capacity is influenced by several interrelated factors:

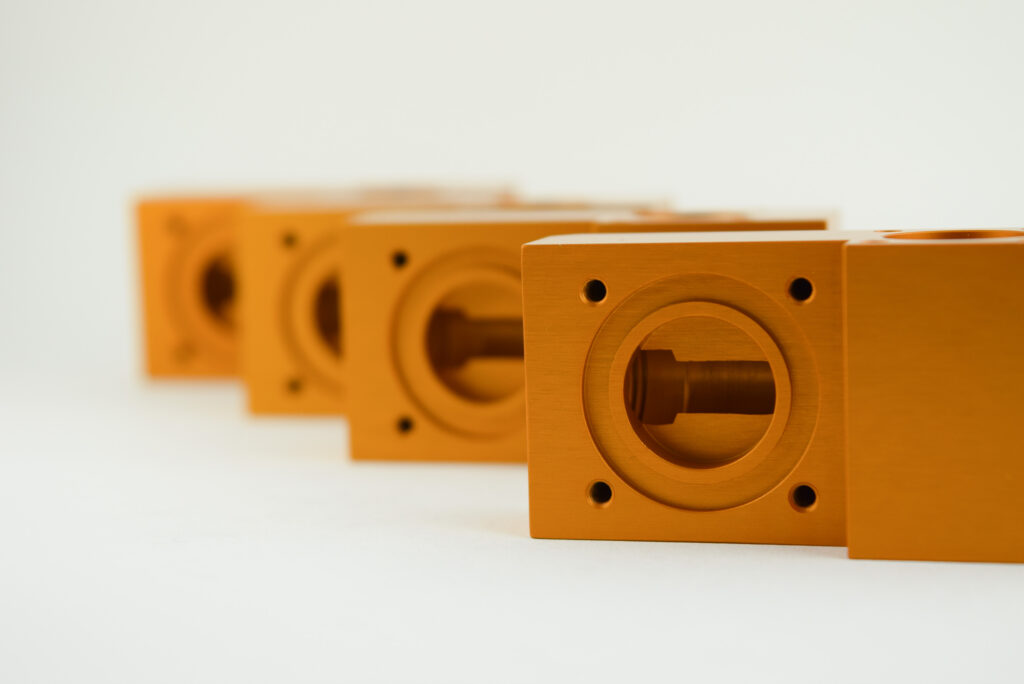

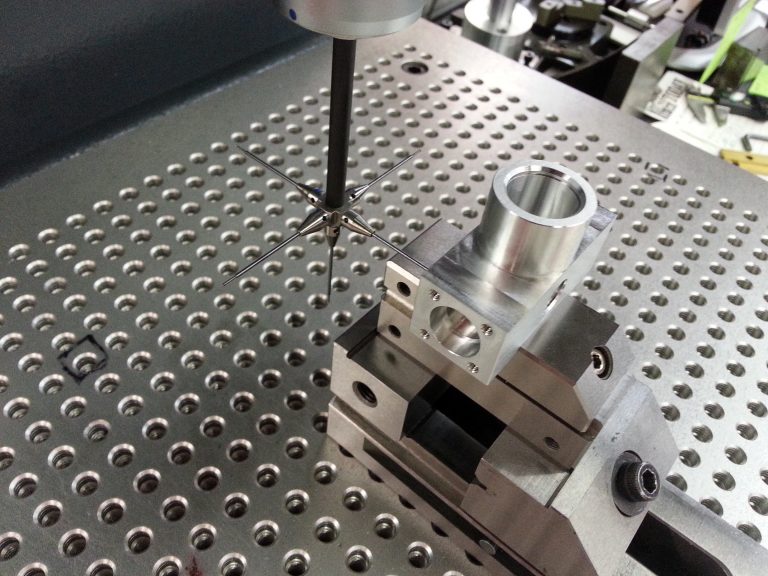

- Machine Availability: This includes not just the number of machines, but also their type, age, and condition. A shop with a fleet of modern CNC machines may outperform a larger shop with outdated equipment. Specialized machines (e.g., 5-axis mills, EDMs) also expand a shop’s capabilities and flexibility.

- Workforce Size and Skill Level: Skilled machinists, programmers, and quality inspectors are just as critical as the machines themselves. A well-trained team can optimize setups, reduce scrap, and adapt quickly to design changes. Shops with cross-trained staff can shift resources dynamically to meet urgent needs.

- Shift Patterns and Operating Hours: A shop running two or three shifts per day can significantly increase throughput compared to one operating only during standard business hours. Weekend or holiday shifts can also be a sign of a shop’s commitment to meeting tight deadlines.

- Tooling and Fixture Readiness: Even the best machines can’t run efficiently without the right tooling. Shops that maintain a well-organized inventory of cutting tools, jigs, and fixtures—or that can quickly fabricate custom setups—can reduce downtime and accelerate production.

- Production Planning and Scheduling Systems: Behind the scenes, a shop’s ERP or MRP system plays a major role in managing capacity. Sophisticated scheduling tools help allocate resources, forecast bottlenecks, and prioritize jobs based on urgency and complexity.

A shop running at or near full capacity may seem like a sign of success, but it can also be a red flag. If there’s no room to absorb new work or unexpected changes, lead times can stretch and quality may suffer. On the other hand, a shop with too much idle capacity might be struggling with inconsistent demand, poor planning, or operational inefficiencies.

Asking Questions

For buyers, the key is to find a balance: a shop that is busy enough to demonstrate demand and competence, but not so overloaded that your order becomes a low priority. Asking the right questions—such as how they handle rush jobs, what their average machine utilization rate is, or how they scale for large orders—can reveal a lot about whether a shop is truly equipped to meet your needs.

Questions Buyers should ask:

- Can the shop handle my volume?

- Do they have the right equipment for my parts?

- Is their capacity consistent or seasonal?

Decoding Lead Time

Lead time is one of the most critical metrics a mechanical parts buyer must evaluate when selecting a machine shop. It represents the total time from when a purchase order is placed to when the finished parts are delivered and ready for use. While it may seem like a simple number, lead time is actually the sum of several interconnected processes—and each one can impact your production schedule.

Here’s a breakdown of what lead time typically includes:

- Order Processing: This is the initial phase where the shop reviews the order, confirms specifications, and schedules the job. Delays here can occur due to unclear drawings, missing information, or internal backlogs.

- Material Procurement: If the shop doesn’t have the required raw materials in stock, they must source them. Lead times for materials can vary widely depending on the type (e.g., aluminum vs. exotic alloys), supplier reliability, and global supply chain conditions.

- Machining and Finishing: This is the core of the production process. The complexity of the part, the number of operations required, and the availability of machines all influence how long this stage takes. Secondary processes like heat treating, anodizing, or coating can add days or even weeks.

- Inspection and Quality Control: High-precision parts often require thorough inspection, including CMM reports, first article inspections (FAIs), or even third-party certifications. A shop with a robust quality system may take slightly longer here—but it’s often worth the wait.

- Packaging and Shipping: Once approved, parts must be carefully packaged to prevent damage and shipped according to the buyer’s requirements. This final step can be affected by logistics delays, especially for international shipments

Shorter lead times are ideal, especially for just-in-time (JIT) manufacturing environments. However, extremely short lead times can sometimes indicate rushed work or insufficient quality checks.

What Buyers Consider When Evaluating Lead Time:

- Is the quoted lead time realistic? Some shops may offer aggressive timelines to win business, only to miss deadlines later. Experienced buyers look for consistency between quoted and actual delivery times.

- How does it compare to industry norms? Lead times vary by part complexity and volume. A 2-week lead time for a simple turned part might be standard, while a 6-week lead time for a complex assembly could be acceptable.

- Can the shop scale or expedite if needed? Flexibility is key. Buyers often ask whether a shop can accommodate rush orders, split deliveries, or ramp up production if demand increases.

- What’s the shop’s track record? Past performance is a strong indicator of future reliability. Buyers may review on-time delivery rates, customer references, or supplier scorecards to assess this.

- Are there hidden delays? Some shops outsource secondary operations, which can introduce variability. Understanding the full supply chain behind your parts helps avoid surprises.

Ultimately, lead time isn’t just about speed—it’s about predictability. A slightly longer but consistently met lead time is often more valuable than a short one that’s frequently missed. For buyers managing tight production schedules, the ability to plan with confidence is everything.

How Buyers Use Capacity and Lead Time Together

A smart buyer doesn’t look at capacity and lead time in isolation. Instead, they evaluate how these two factors interact:

| Scenario | Interpretation |

|---|---|

| High capacity + Short lead time | Ideal: Shop is ready and responsive |

| High capacity + Long lead time | Potential inefficiencies or backlog |

| Low capacity + Short lead time | Risk of overcommitment |

| Low capacity + Long lead time | Likely to cause delays |

Buyers often request production schedules, machine utilization reports, or even on-site audits to verify a shop’s claims. They may also use supplier scorecards to track performance over time.

Making the Final Decision

When comparing multiple shops, buyers typically weigh:

- Quoted lead time vs. actual delivery history

- Capacity to handle rush orders or design changes

- Communication and transparency

- Quality certifications (e.g., ISO 9001, AS9100)

- Cost-effectiveness over the long term

In many cases, the best partner isn’t the cheapest or the fastest—it’s the one who consistently delivers on time, within spec, and with clear communication.

Conclusion

For mechanical parts buyers, capacity and lead time are more than just numbers—they’re indicators of a machine shop’s reliability, efficiency, and ability to grow with your business. By understanding how to interpret and balance these metrics, buyers can make informed decisions that keep production lines moving and customers satisfied.

Next step, read: How Certifications Guide Mechanical Parts Buyers to the Right Machine Shop.