The Importance of a Machine Shop’s Tech Stack in Today’s Digital Age

In the modern manufacturing landscape, a machine shop’s tech stack plays a pivotal role in determining its efficiency, accuracy, and overall performance. As a mechanical parts buyer, understanding the software and technologies a shop uses for engineering, production, and quality control can help you make an informed decision. This article explores the key considerations of a machine shop’s tech stack and how it can specifically impact your sourcing strategy.

Why the Tech Stack Matters

A robust tech stack can significantly enhance a machine shop’s operations by streamlining processes, improving precision, and enabling better adaptability to your needs. The integration of advanced technologies can lead to:

- Increased Efficiency: Automation and optimized workflows reduce manual intervention, speeding up production and minimizing errors.

- Enhanced Precision: Cutting-edge software ensures high accuracy in design and manufacturing, resulting in superior quality parts.

- Better Adaptability: Advanced tools allow for quick adjustments to designs and processes, accommodating changes in project requirements.

Key Components of a Machine Shop’s Tech Stack

When evaluating a machine shop’s tech stack, consider the following components:

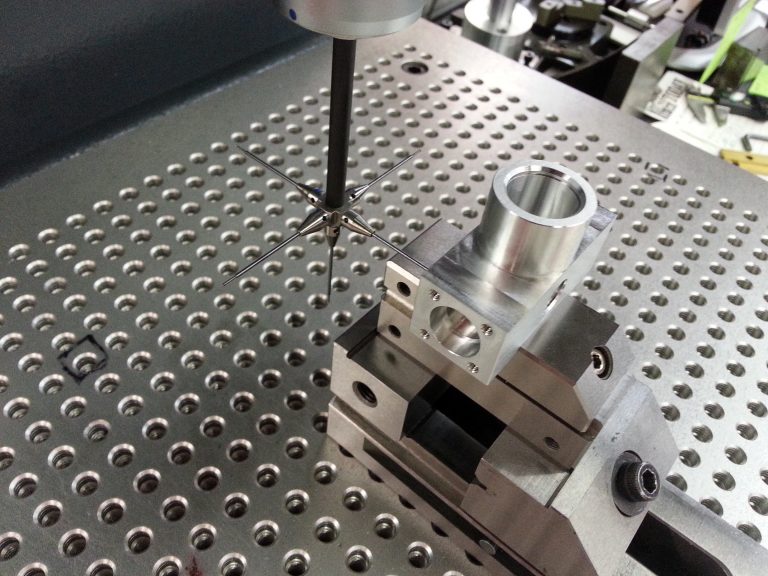

1. CAD/CAM Software

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are fundamental to modern machine shops. CAD software enables precise design and modeling of parts, while CAM software translates these designs into detailed instructions for machinery. Look for shops that use advanced CAD/CAM solutions, such as SolidWorks, AutoCAD, or Mastercam, which offer robust features for complex designs and efficient production on milling and turning machines.

2. ERP Systems

Enterprise Resource Planning (ERP) systems integrate various business processes, including inventory management, order processing, and scheduling. A machine shop with a comprehensive ERP system can manage resources more effectively, ensuring timely delivery and optimal use of materials. Popular ERP solutions like SAP, Oracle, and Microsoft Dynamics can provide valuable insights and streamline operations.

3. Real-Time Monitoring Tools

Real-time monitoring tools track the performance of machinery and production processes, simultaneously enabling immediate detection of issues and adjustments. Additionally these tools can include sensors, IoT devices, and software platforms that provide live data on machine status, production rates, and quality metrics. Shops that utilize real-time monitoring can maintain high standards of quality and efficiency, reducing downtime and improving overall productivity.

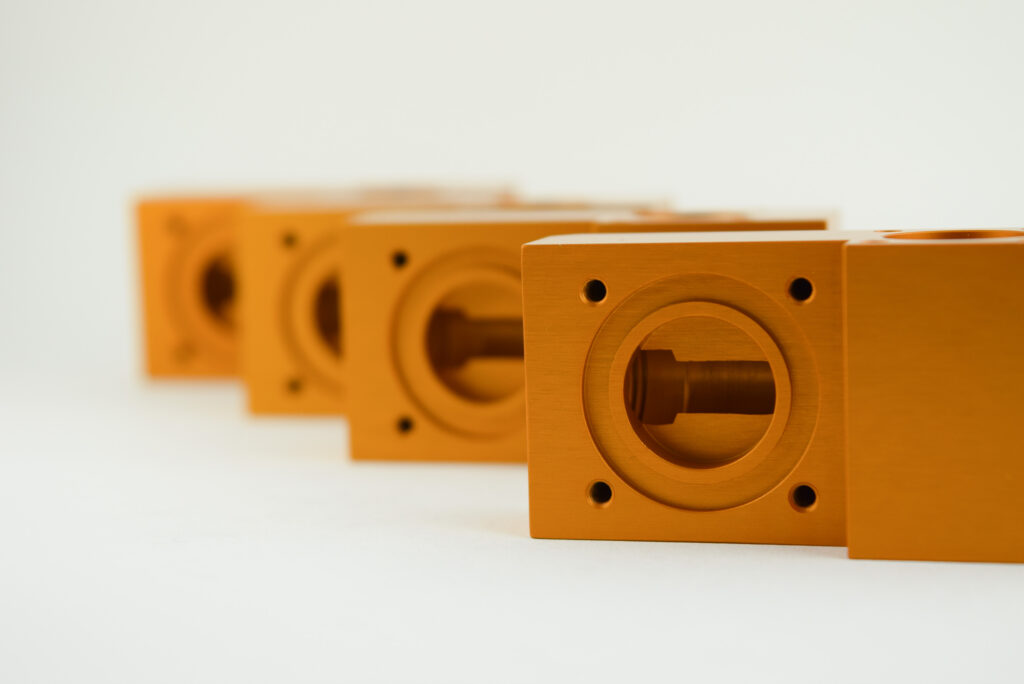

4. Quality Control Software

Quality control is crucial in manufacturing, and specialized software can automate and enhance this process. Consequently, buyers should look for shops that use quality management systems (QMS) like ISO 9001-compliant software, which ensures rigorous testing and inspection of parts. These systems can track defects, manage corrective actions, and maintain detailed records, significantly ensuring consistent quality.

5. Data Analytics and Reporting

Data analytics tools analyze production data to identify trends, optimize processes, and forecast future needs. Subsequently reporting software can generate detailed reports on performance metrics, helping shops make informed decisions. A machine shop that leverages data analytics can continuously improve its operations and adapt to changing demands.

Evaluating a Machine Shop’s Tech Stack

To assess a machine shop’s tech stack, consider the following steps:

- Research: Investigate the specific software and technologies the shop uses. Look for industry-standard solutions and inquire about their features and benefits.

- Ask Questions: Engage with the shop to understand how they utilize their tech stack. Ask about their experience with the software, any customizations they’ve made, and therefore how it impacts their operations.

- Request Demonstrations: If possible, request demonstrations of the software and tools in action. Seeing the tech stack in use can provide valuable insights into its effectiveness.

- Check Compatibility: Ensure the shop’s tech stack is compatible with your own systems and requirements. Compatibility can streamline collaboration and data exchange, enhancing overall efficiency.

Aligning Their Tech Stack with Your Needs

A machine shop’s tech stack should align with your specific needs and goals. Consider the following factors:

- Project Requirements: Ensure the shop’s software and technologies can handle the complexity and precision required for your projects.

- Scalability: Look for shops that can scale their operations to accommodate your growth. A flexible tech stack can undoubtedly adapt to increasing demands and evolving requirements.

- Innovation: Partner with shops that prioritize innovation and continuous improvement. A forward-thinking approach to technology can lead to better solutions and long-term success.

Conclusion

In today’s digital age, a machine shop’s tech stack is a critical factor in determining its efficiency, accuracy, and adaptability. By investigating the software and technologies used for engineering, production, and quality control, you can make an informed decision that ensures superior performance and alignment with your needs. A shop with a robust tech stack is likely to offer better quality, faster production times, and greater flexibility. Markedly, these attributes will lead to a successful partnership.

Next step, read: The Importance of Long-Term Business Plans in Choosing a Machine Shop.