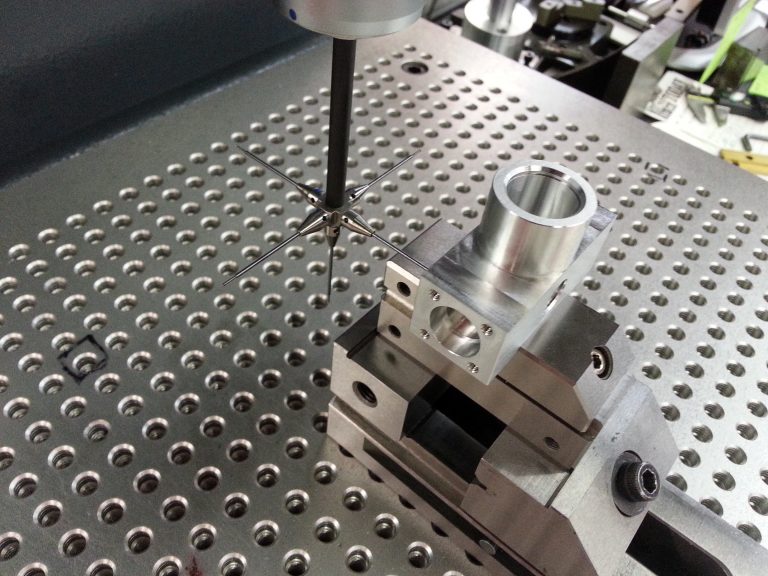

As part of our strategy to maintain high standards and consistency in scheduling, production, and delivery, Machine Inc. uses multi-palleted CNC milling machines to provide the CNC milling of aerospace components.

This investment in high-quality, multi-palleted tooling machine centers help us provide superior, consistent quality CNC milling of aerospace components. Further, doing so keeps delivery on schedule. Multi-pallet machines allow for tooling to remain in place between runs. This enables us to:

- Save time and resources, not having to breakdown and, thusly, re-setup machines for every job

- Preserve the settings on each pallet, further ensuring consistency in tolerances and quality

- Keep deliveries on time-with consistent quality standards intact, delivery schedules remain as promised

- Have quick-turn production runs if Kanban releases get accelerated

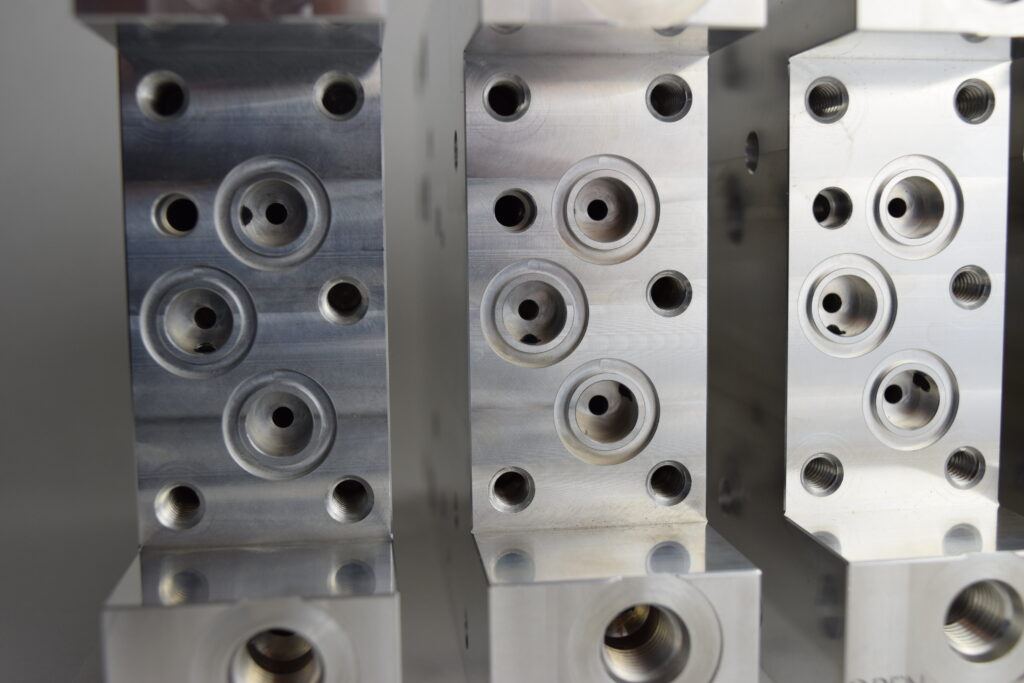

- Run a variety of jobs at once, horizontal and vertical machines are able to handle many configurations simultaneously

- Handle larger quantities and types of projects Be flexible with Kanban release dates

Eventually all of which translates into lower component cost to the customer.

Extra Large Tool Magazines

Our Matsuura milling machines feature large tool magazines that allow us to handle a variety of parts. Further, there are duplicates on hand for those prone to breakage. Specifically, the tool magazine capacity is 300 tools. This way, if a tool expires or breaks, the system automatically selects the next ready tool. Significantly ensuring continuous operation without the need for human intervention.

Pallet Systems

Ultimately, pallet systems enable our machines to continuously make chips. Because of this, our machinists can transfer pallets between compatible machines. Also, they can set up and store extra pallets outside the spindle area (where the cutting occurs) and load them as needed. Having a specific number of pallets doesn’t limit the number of parts users can set up overall. Our pallets feature up to four usable faces, increasing the number of possible jobs per pallet. In practice, we have potentially four separate programs running on one pallet. For instance, a machine with 15 pallets could potentially run up to 60 different operations.

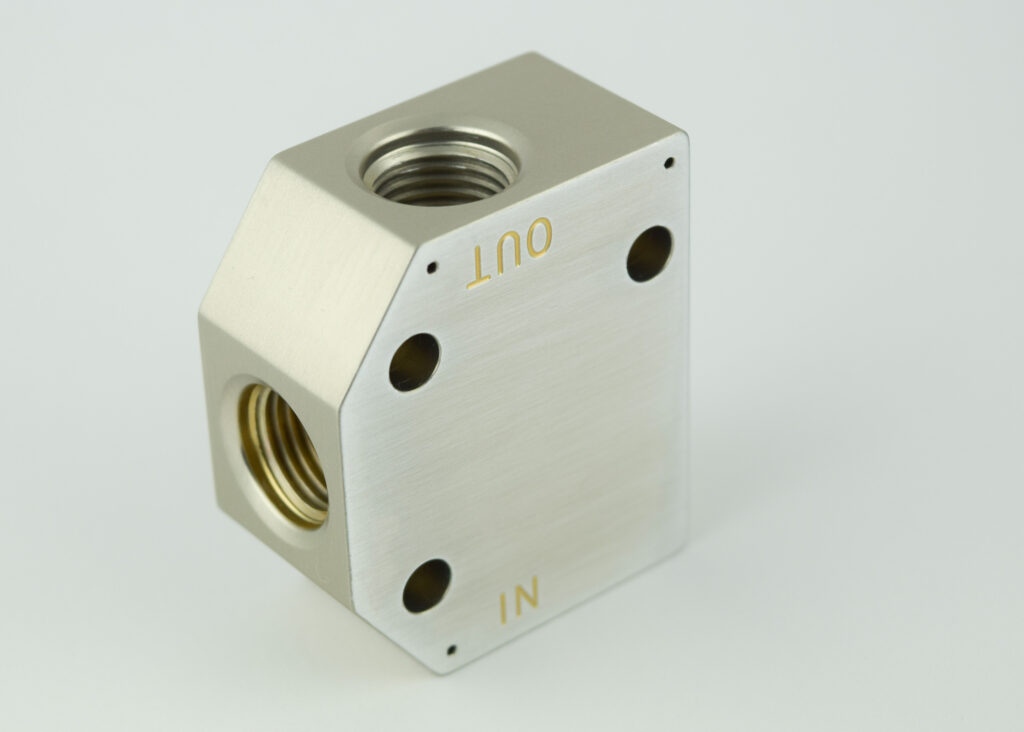

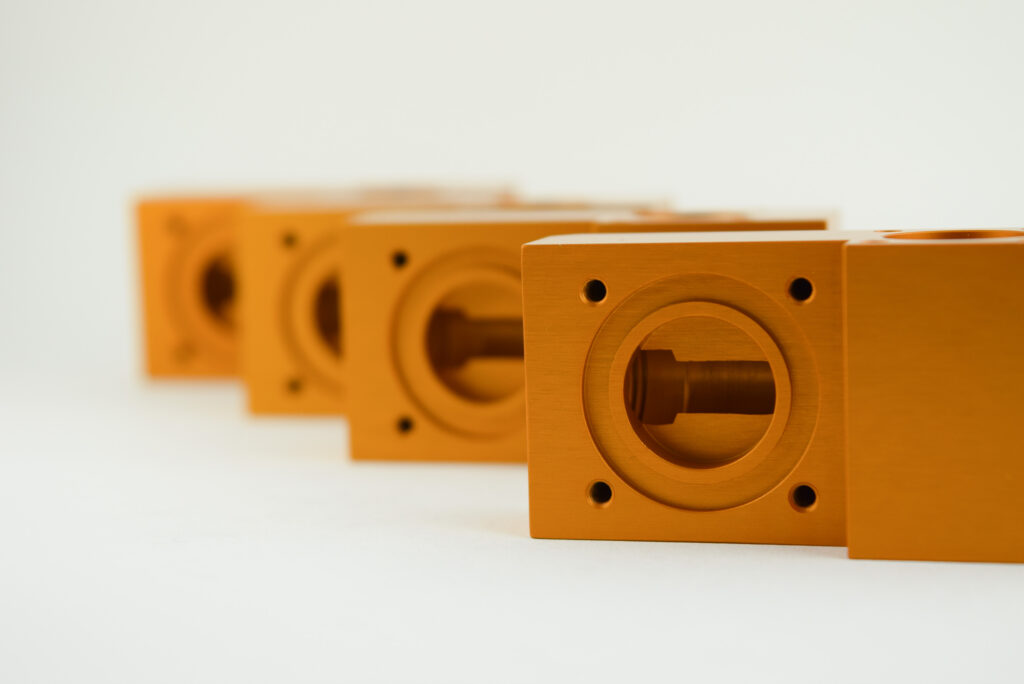

From the earliest stages of your project through completion, our highly skilled technicians at Machine Inc. will offer their expertise to ensure the CNC milling of aerospace components are precisely what you need. This includes everything from design assistance to ensure low-cost manufacturability, to material selection, prototyping, protective finish selection, final assembly, and more.

For more on how we can provide the CNC machining for your precision component needs, don’t hesitate to contact us to communicate with one of our experts.

Learn more about…