Machine Inc., a precision machining, engineering, and assembly solutions machine shop to use solar power.

As part of its on-going commitment to invest in energy efficiency, Machine Inc. installed solar energy panel systems on the roof of its Stoughton facility. It did so with the help of Rexel Energy Solutions, a leading energy efficiency supply house in New England. Machine Inc operates as a contract manufacturer of precision machined parts and assemblies. and was an early Machine Shop to use Solar Power.

Steve Proffetty from Proffetty Electrical, Inc. was contracted to install the 273 solar panels. These panels would produce 75 kilowatts of electricity per year. This will supply almost 50% of its power requirements to run the entire shop. It currently tracks the solar photovoltaic system’s energy output in real-time using the solar power performance online monitoring system. In addition to the energy saving over time, Machine Inc. is eligible for a federal tax credit. It also qualifies for production-based incentives like Solar Renewable Energy Credits (SRECs).

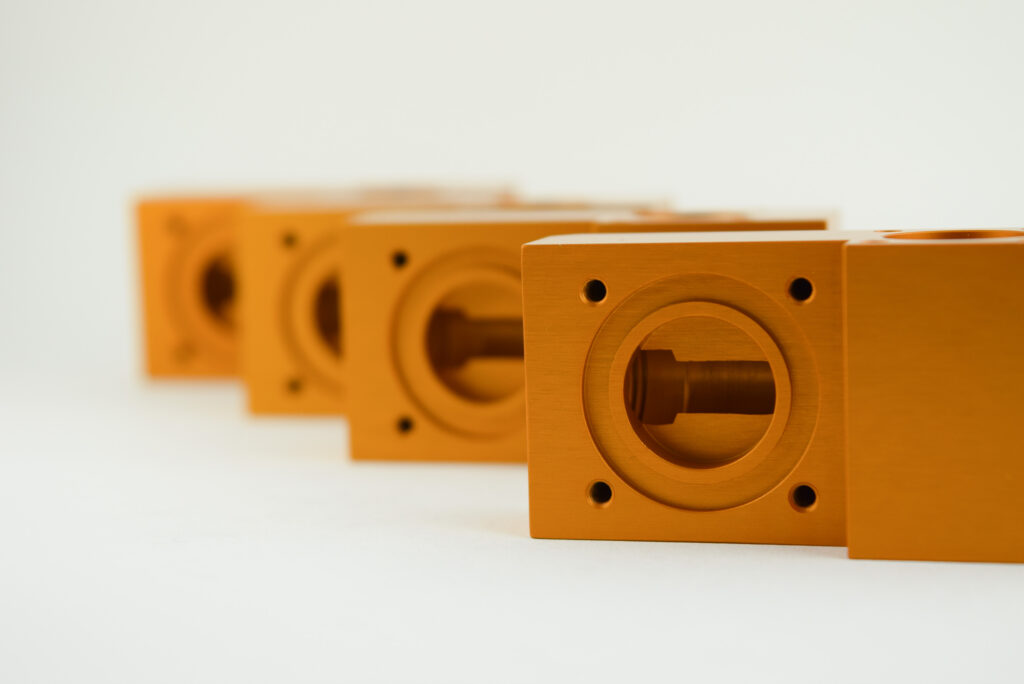

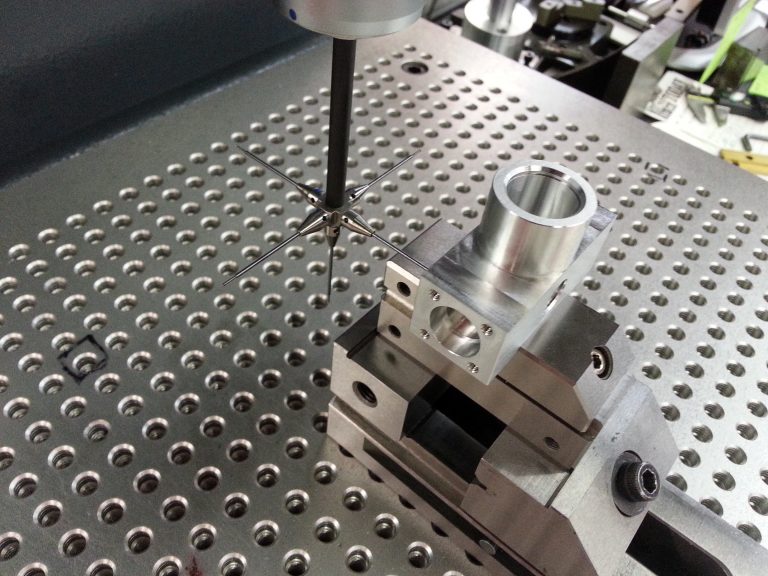

Machine Inc has been a Massachusetts precision machining and assembly company since 1981. Services include milling and turning, as well as deburring and inspection. Kanban arrangements are frequently setup with customers to ensure smooth and continuous flow of precision machined parts. The company also manufactures their own Cockpit Lighting brand, Oplite Technologies, in-house.

The View from Above

In a recent NPR interview, Richard Mileika, President of Machine Inc., said, “We are excited about this investment in using renewable energy. This complements our other sustainable manufacturing practices. These include recycling 90% of our waste, using environmentally-friendly manufacturing coolants and lubricants, and deploying energy-efficient machinery within the shop. At Machine Inc., we operate within the bounds of lean and green manufacturing principles. Because we really early to be a machine shop to use solar power, we ensure each action we take is measurable, sustainable, enduring, and contributes to enhancing our throughput. This also helps us in minimizing our carbon footprint.”

Industry leaders recently learned first hand about the benefits of additional solar power during BTMA Night. This get-together event welcomed visitors to Machine Inc to see what a modern manufacturing facility looks like.

For more on how we can provide the CNC machining for your precision needs, don’t hesitate to contact us to communicate with one of our experts.

Learn more about…