The Right Parts for the Right Shop: A Guide to Strategic Fit in Defense and Aerospace Machining

Manufacturers in the defense and aerospace industries produce mission-critical parts that demand extreme precision, unwavering reliability, and strict compliance with rigorous standards. For a machine shop, success in these sectors isn’t just about technical capability. It’s also about knowing which types of parts align with the shop’s strengths. Recognizing the complexity, tolerances, and regulatory requirements that a shop can consistently meet is essential. A well-matched fit between the shop’s expertise and the part’s demands ensures not only quality and compliance but also long-term trust with buyers. This is crucial for flawless performance.

Assessing Technical Capability Through Part Complexity

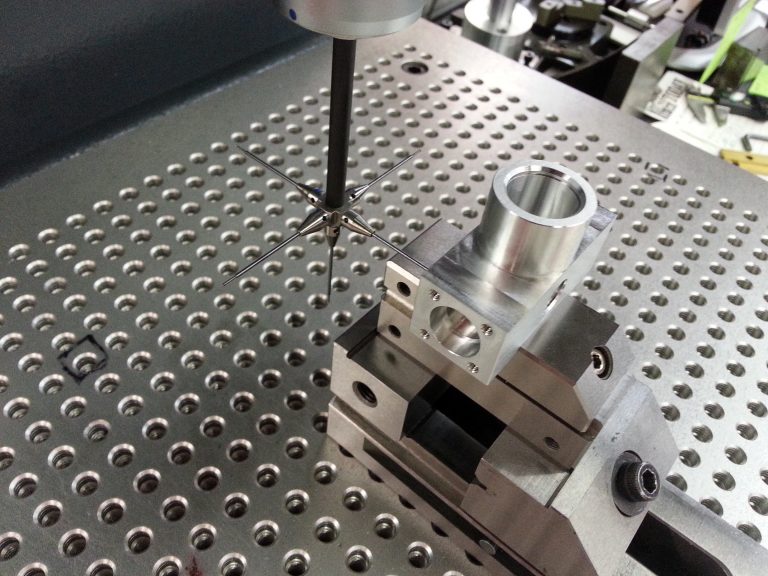

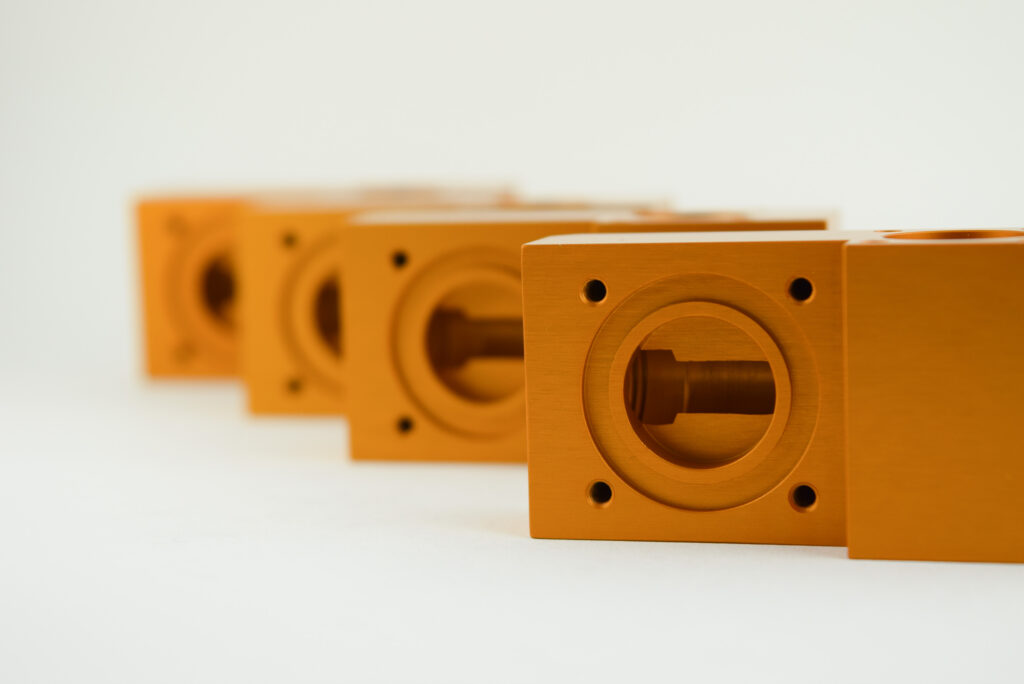

The process begins with a deep understanding of the parts being sourced. Aerospace and defense components often involve complex geometries, exotic materials, and extremely tight tolerances. Whether it’s a titanium actuator housing for a fighter jet or a stainless steel bracket for a satellite payload, the buyer must ensure the shop has the technical capability and experience to deliver. This means looking for shops equipped with advanced multi-axis CNC milling and turning machines. Precision inspection tools like CMMs and optical scanners are essential.

Equally important is the shop’s familiarity with industry standards. Certifications such as AS9100, ITAR registration, and NADCAP accreditation are essential indicators of a shop’s readiness to serve defense and aerospace clients. These credentials demonstrate that the shop adheres to rigorous quality management systems. They also show that it can handle sensitive or classified work. A buyer will often prioritize shops that not only hold these certifications but also have a proven track record. Passing audits and delivering compliant parts are crucial.

Material expertise is another critical factor. Aerospace and defense parts can be made from high-performance alloys like Inconel, titanium, or hardened steels. These materials require specialized tooling, machining strategies, and post-processing knowledge. A buyer must assess whether a shop has experience working with these materials. It’s important to maintain dimensional stability and surface integrity throughout the manufacturing process.

Evaluating Scalability and Production Flexibility

Beyond technical capability, buyers also evaluate a shop’s ability to scale production and meet delivery timelines. Defense contracts often involve long-term programs with evolving requirements. In contrast, aerospace projects may demand rapid prototyping followed by full-rate production. A shop that can adapt to changing volumes and maintain consistent quality over time becomes a valuable strategic partner. This knowledge helps machine shop knowing which types of parts they can consistently produce.

Finally, communication and documentation are vital. Aerospace and defense projects involve detailed drawings, change orders, and traceability requirements. A machine shop must be able to manage this complexity with robust documentation practices and clear communication channels. A willingness to collaborate closely with engineering and quality teams is also crucial.

In short, the best machine shop for a defense or aerospace buyer is one that combines technical excellence with industry-specific knowledge and regulatory compliance. Operational flexibility is also important. By aligning the shop’s capabilities with the unique demands of the parts being sourced, buyers can ensure mission success—on the ground, in the air, or beyond Earth’s atmosphere.

Next step, read: How Mechanical Parts Buyers Use Machining Capabilities to Choose the Right Machine Shop.