The Importance of Long-Term Business Plans in Choosing a Machine Shop

When you need to find a source for mechanical parts, it’s essential to look beyond immediate capabilities and consider a shop’s long-term business plans when choosing a machine shop. A shop with a clear vision for growth and innovation is more likely to invest in new technologies and processes, ensuring continuous improvement. This article delves into the importance of evaluating a machine shop’s future plans and how they can align with your business goals for mutual growth and success.

Why Long-Term Business Plans Matter

A machine shop’s long-term business plans provide insight into its commitment to growth, innovation, and sustainability. These plans often include strategies for expanding capabilities, adopting new technologies, and improving processes. By partnering with a shop that has a forward-thinking approach, you can benefit from:

- Continuous Improvement: Shops that invest in their future are likely to continuously enhance their operations, leading to better quality, efficiency, and reliability.

- Adaptability: A shop with a vision for growth can adapt to changing market demands and technological advancements, ensuring they remain competitive and capable of meeting your evolving needs.

- Sustainability: Long-term plans often include sustainability initiatives, which can align with your own goals for environmentally responsible sourcing.

Key Considerations in Evaluating Long-Term Business Plans

When choosing a machine shop to make mechanical parts, review the shop’s long-term business plans and consider the following aspects:

1. Investment in Technology

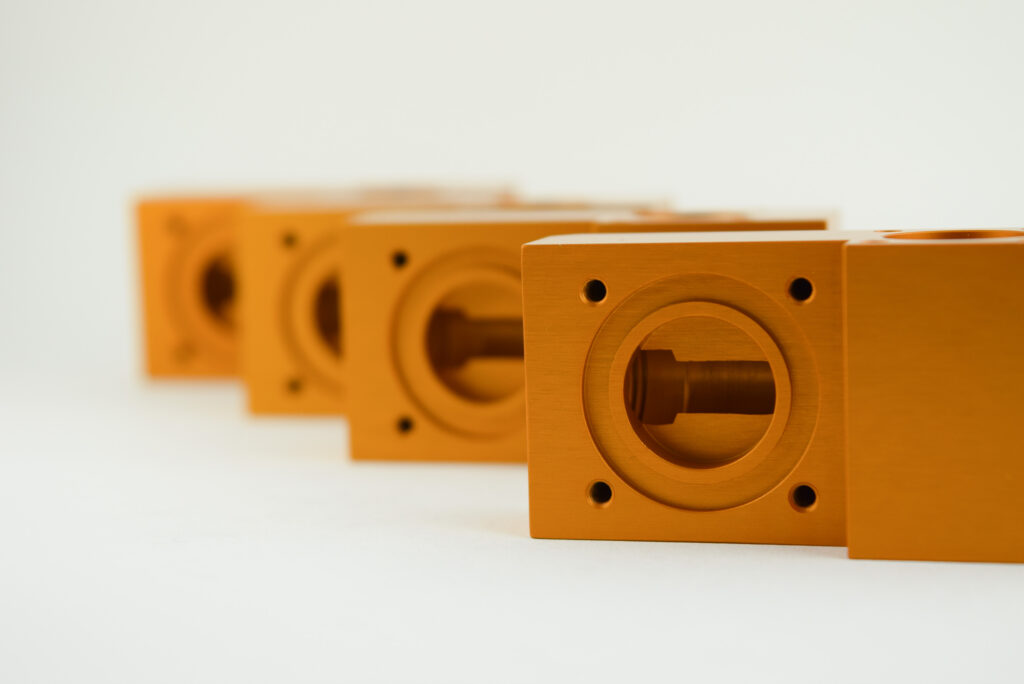

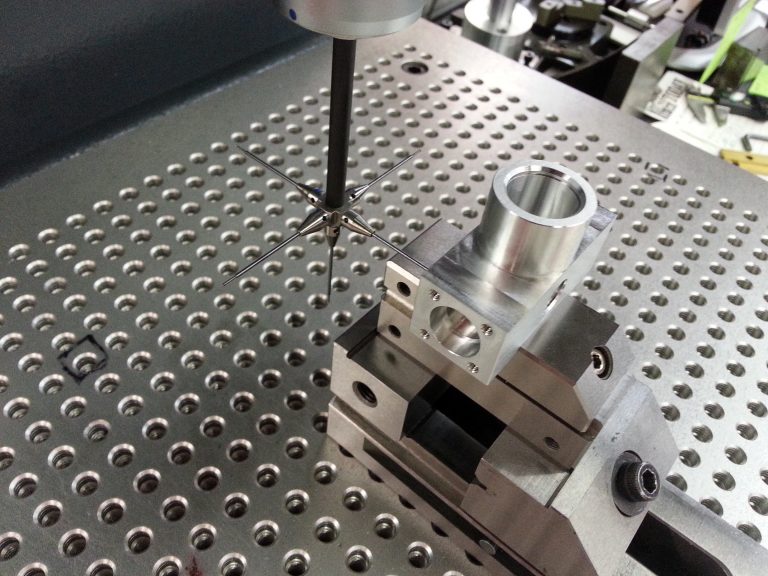

A shop that prioritizes investment in technology is likely to stay ahead of the curve. Look for plans that include upgrading machinery, adopting advanced software, and implementing automation. Pallet machines, multi-axis turning centers, and robot arms are just a few examples. These investments can lead to higher precision, faster production times, and reduced costs, which are crucial factors when choosing a machine shop.

2. Expansion of Capabilities

Evaluate whether the shop plans to expand its capabilities. This could involve adding new services, such as prototyping, assembly, or finishing, or increasing their capacity to handle larger or more complex orders. A shop with expanding capabilities can offer more comprehensive solutions, reducing the need for multiple suppliers. This is vital when it comes to choosing the right machine shop for your needs.

3. Workforce Development

A forward-thinking shop will invest in its workforce through training and development programs. Skilled employees are crucial for maintaining high standards of quality and innovation. When choosing a machine shop, ask about their plans for employee development and how they ensure their team stays updated with the latest industry trends and technologies.

4. Sustainability Initiatives

Sustainability is becoming increasingly important in manufacturing. Look for shops that have plans to reduce their environmental impact through energy-efficient practices, waste reduction, and sustainable sourcing. Partnering with a shop that prioritizes sustainability is an important factor when choosing a machine shop, as it can enhance your own company’s reputation and align with your corporate social responsibility goals.

5. Strategic Partnerships

Consider whether the shop is open to forming strategic partnerships. Collaborations with other companies, research institutions, or technology providers can drive innovation and growth. When choosing a machine shop to make mechanical parts, selecting one that actively seeks partnerships is likely to be more dynamic and capable of offering cutting-edge solutions.

Aligning Their Plans with Your Business Goals

To ensure a successful partnership, it’s crucial that the machine shop’s long-term plans align with your own business goals. Here are some steps to achieve this alignment:

- Communication: Engage in open and transparent discussions about your expectations and long-term objectives. Ensure the shop understands your vision and is willing to support it when choosing a machine shop.

- Shared Values: Look for shops that share your values, whether it’s a commitment to quality, innovation, or sustainability. Shared values can strengthen the partnership and lead to more collaborative efforts.

- Flexibility: Choose a shop that demonstrates flexibility and adaptability. Your business needs may change over time, and a shop that can adjust its plans to accommodate these changes will be a valuable partner in choosing a machine shop for the long term.

- Performance Metrics: Establish clear performance metrics and goals to track the progress of the partnership. Regular reviews can help ensure both parties are on track and identify areas for improvement. This strategic approach is essential when choosing a machine shop.

Conclusion

Evaluating a machine shop’s long-term business plans is a critical step in selecting the right partner for your mechanical parts needs. By considering their investment in technology, expansion of capabilities, workforce development, sustainability initiatives, and strategic partnerships, you can ensure they are committed to continuous improvement and innovation. Aligning their plans with your own business goals can lead to a successful, long-term partnership that drives mutual growth and success when choosing a machine shop.

Next step, read: The Right Parts for the Right Shop: A Guide to Strategic Fit in Defense and Aerospace Machining.