How Mechanical Parts Buyers Use Machining Capabilities to Choose the Right Machine Shop

In the world of manufacturing, the role of a mechanical parts buyer is pivotal. These professionals are responsible not only for sourcing components but also for ensuring that the suppliers they choose can meet stringent quality, cost, and delivery requirements. One of the most critical decisions a buyer makes is selecting the right machine shop. This choice hinges on a deep understanding of machining equipment and process capabilities—especially CNC machining. Here’s how savvy buyers approach this task.

Understanding the Project Requirements

Before evaluating any machine shop, a buyer must have a clear grasp of the part specifications:

- Material type (e.g., aluminum, stainless steel, titanium)

- Tolerances and finishes

- Volume and frequency of orders

- Lead time expectations

- Discrete Component or part of an Assembly

These factors directly influence the type of machining processes required—whether it’s CNC milling, turning, EDM, or grinding.

The Role of CNC Machining in Supplier Selection

CNC (Computer Numerical Control) machining is a cornerstone of modern manufacturing, offering precision, repeatability, and scalability. For mechanical parts buyers, evaluating a machine shop’s CNC capabilities is essential to ensuring the supplier can meet both technical and commercial requirements. Here’s a deeper look at the four key areas buyers focus on:

Machine Types

The type and configuration of CNC machines in a shop determine what kinds of parts they can produce and how efficiently they can do it.

- CNC Mills: These machines are ideal for producing complex 3D geometries, pockets, slots, and contours. Vertical mills are common for general-purpose work, while horizontal mills offer better chip evacuation and are often used for high-volume production.

- CNC Lathes: Used for turning operations, these machines are perfect for cylindrical parts like shafts, bushings, and threaded components. Many modern lathes include live tooling, allowing for milling and drilling in a single setup.

- Multi-Axis Machines (3-, 4-, 5-axis): These machines allow for the machining of complex parts in fewer setups, improving accuracy and reducing lead time. Five-axis machines are especially valuable for aerospace, medical, and mold-making applications.

- Swiss-Type Lathes: These are specialized for small, high-precision parts, often used in the medical, electronics, and defense industries. They excel in producing long, slender components with tight tolerances.

Control Systems

The CNC control system serves as the brain of the machine, playing a critical role in determining programming flexibility, system integration, and operator efficiency. These systems offer distinct advantages in terms of user interface design, programming language structure, and compatibility with various CAD/CAM platforms. When evaluating a machine shop, buyers consider whether the control systems in use can seamlessly interpret and execute their CAD/CAM files without requiring complex translations or risking data loss. Additionally, some controllers support macro programming and custom cycles, which can significantly enhance efficiency, especially for repeat or high-volume jobs. The level of support and training available for a given control system also matters; shops that use well-supported platforms are generally better equipped to maintain uptime, troubleshoot issues quickly, and adapt to new or evolving job requirements.

Programming Expertise

Even the most advanced CNC machine is only as good as the person programming it. Buyers often assess the shop’s programming capabilities to gauge how well they can optimize production.

- CAM Software: Programs like Mastercam, Fusion 360, SolidCAM, and Siemens NX are used to generate toolpaths. A shop’s proficiency with these tools can reduce cycle times and improve surface finishes.

- Simulation and Verification: Advanced programming includes simulation to detect collisions, optimize tool changes, and validate toolpaths before machining begins—reducing scrap and setup time.

- Design for Manufacturability (DFM): Skilled programmers can suggest design tweaks that simplify machining, reduce costs, and improve part performance.

Tooling and Fixturing

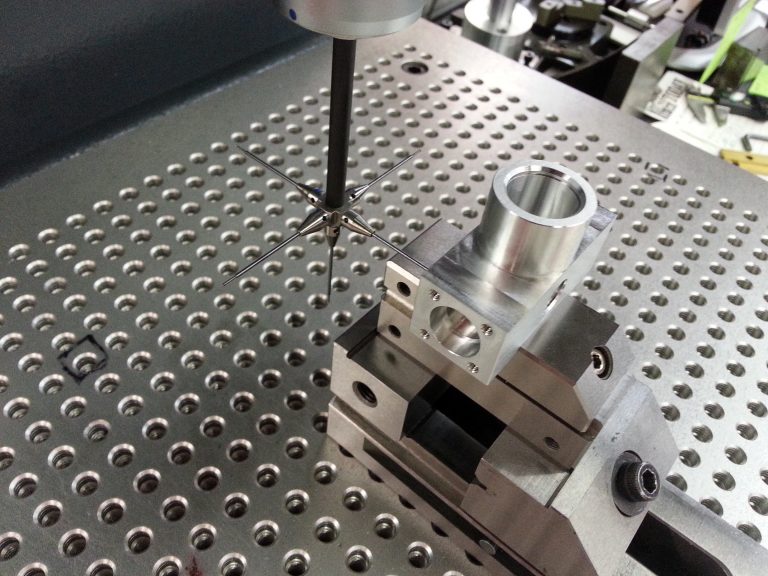

Tooling and fixturing are fundamental to achieving the precision, repeatability, and efficiency that CNC machining demands. High-performance cutting tools, such as carbide inserts or coated end mills, play a crucial role in reducing cycle times and enhancing surface finishes. Shops that invest in advanced tool management systems can monitor tool wear in real time, optimize tool life, and minimize unplanned downtime—contributing to more consistent output and lower operating costs. When combined with automation technologies such as tool changers, pallet systems, and robotic arms, these capabilities enable lights-out machining, where machines can run unattended for extended periods, including overnight or during weekends. This level of automation is especially advantageous for high-volume production, as it increases throughput while reducing labor costs and human error.

Equally important is fixturing, which ensures that parts are held securely and consistently during machining. Custom fixtures are often designed to maintain precise part orientation and clamping pressure, which is essential for maintaining tight tolerances. Modular fixturing systems, on the other hand, offer flexibility and speed, allowing for quick changeovers between jobs and maximizing machine uptime. A shop’s ability to design and implement effective fixturing solutions is a strong indicator of its technical capability and readiness to handle complex or high-precision work.

Automation Integration

Tool changers, pallet systems, and robotic arms can be integrated with CNC machines to enable lights-out machining—ideal for high-volume or overnight production. This refers to the automation technologies that allow CNC machines to operate with minimal or no human intervention, especially during off-hours. Let’s break down each component and how they contribute to lights-out machining:

Automatic Tool Changers (ATCs)

An automatic tool changer allows a CNC machine to switch between different cutting tools during a machining cycle without manual input. This is essential for:

- Unattended operation: Enables the machine to run complex jobs overnight or during breaks without stopping.

- Multi-step operations: A single part may require drilling, milling, tapping, and contouring—all with different tools.

- Reduced downtime: Eliminates the need for an operator to manually change tools, which saves time and reduces errors.

Pallet Systems

- Quick changeovers: While one pallet is being machined, another can be loaded or unloaded, minimizing idle time.

- High-mix, low-volume efficiency: Ideal for shops that need to run different parts back-to-back without lengthy setup times.

- Extended run times: With multiple pallets queued, the machine can continue running for hours without operator input.

Robotic Arms

Industrial robots can be integrated with CNC machines to handle tasks such as:

- Loading and unloading raw material

- Loading and unloading finished parts

- Part inspection using vision systems

- Deburring or cleaning operations

Lights-Out Machining

When these systems are combined, they enable lights-out machining—a term used to describe fully automated manufacturing that can run without human supervision, often overnight or during weekends. Benefits include:

- Increased machine utilization: Maximizes spindle uptime and ROI on expensive equipment.

- Lower labor costs: Reduces the need for second or third shifts.

- Faster turnaround: Jobs can be completed outside of normal working hours.

- Scalability: Makes it easier to ramp up production without adding headcount.

Evaluating Overall Machining Equipment

Beyond CNC machines, buyers also evaluate the broader range of machining equipment to get a complete picture of a shop’s capabilities. One of the first things they consider is the age and maintenance of the machines. Well-maintained equipment, regardless of its age, tends to produce more consistent and accurate results, while neglected machines can lead to quality issues and downtime. Inspection tools are another critical area of focus. The presence of advanced metrology equipment such as coordinate measuring machines (CMMs), optical comparators, and laser scanners indicates a shop’s ability to verify tight tolerances and maintain high quality standards. Finally, buyers assess the shop’s capacity and scalability—specifically whether it can handle both low-volume prototyping and full-scale production runs. A shop that can scale with demand offers greater flexibility and long-term value as a manufacturing partner.

Assessing Process Capabilities

Buyers look at how well a shop manages its operations:

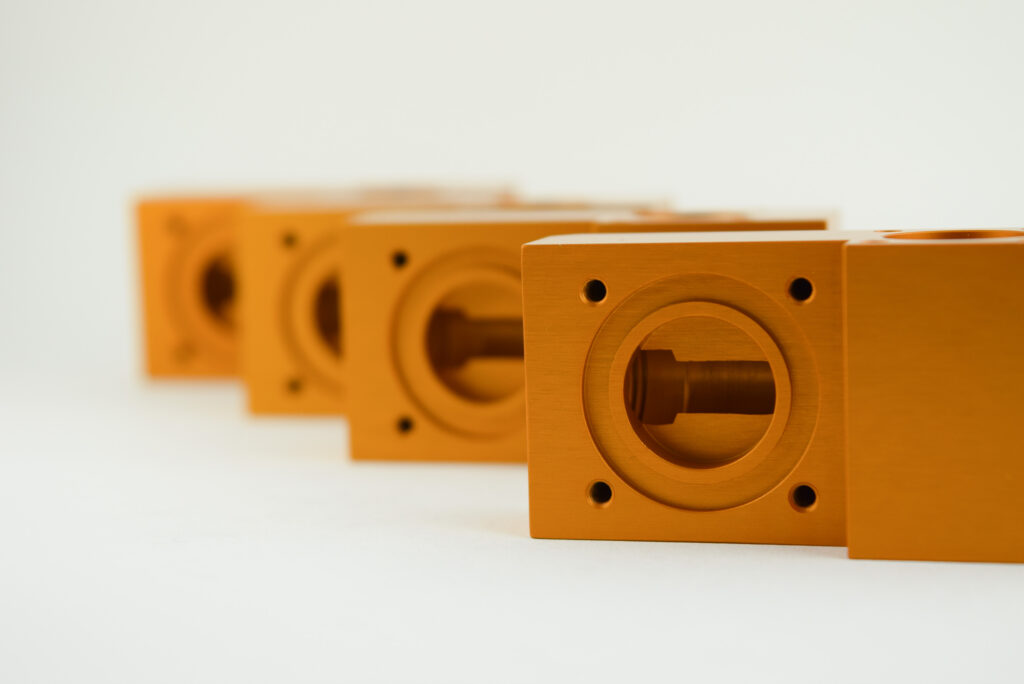

- Certifications: ISO 9001 or AS9100 indicate robust quality systems.

- Process documentation: Standard operating procedures and inspection plans are signs of a mature operation.

- Material traceability: Especially important in regulated industries like Naval, aerospace and medical.

- Post-processing: In-house or partnered services for heat treating, anodizing, or coating can streamline the supply chain.

Visiting the Shop

A site visit offers valuable insights that go far beyond what can be gathered from brochures, websites, or phone calls. A firsthand look at the shop floor reveals the facility’s organization and maintenance—clear signs of operational discipline and attention to detail. It also provides an opportunity to assess the skill level of the employees, from machinists and programmers to quality inspectors.

Buyers evaluate efficiency, identify potential bottlenecks, and understand job prioritization and management by watching how work flows through the shop. Additionally, seeing in-process inspection practices in action gives a clear picture of the shop’s commitment to quality control and process consistency.

Reviewing Past Work and References

To gain confidence in a machine shop’s capabilities, buyers often request evidence of past performance. This may include sample parts or case studies that demonstrate the shop’s experience with similar materials, tolerances, or part geometries. Customer references are also valuable, offering insight into the shop’s reliability, communication, and ability to meet deadlines. In addition, buyers typically review performance metrics such as on-time delivery rates and defect percentages to assess the shop’s consistency and quality track record. These indicators help buyers make informed decisions and reduce the risk of production delays or quality issues. Ultimately, it will assist a buyer choose a shop based on machining capabilities.

Balancing Cost and Capability

While cost is a factor, buyers understand that advanced CNC capabilities can reduce total cost of ownership through:

- Fewer defects

- Faster cycle times

- Reduced setup and changeover

- Better scalability

Conclusion

Choosing the right machine shop is a strategic decision that goes beyond price. By thoroughly evaluating CNC machining capabilities and overall process maturity, mechanical parts buyers ensure they partner with shops that can deliver precision, reliability, and efficiency. In today’s competitive landscape, this diligence is not just smart—it’s essential.

Next step, read: How a Mechanical Parts Buyer Uses Capacity and Lead Time to Choose the Right Machine Shop.