NPR Interview “All Things Considered” on Lean Manufacturing

In a recent NPR Interview on lean manufacturing, listeners heard about how a modern machine shop specializing in CNC machining of precision components and assemblies for the aerospace, medical and analytical instrument industries, was featured on National Public Radio’s (NPR) “All Things Considered.” Machine Inc. is a living example of an important industry giving US manufacturing a boost by adopting lean manufacturing, state of the art machinery, and ship-to-stock inventory management.

NPR correspondent, Chris Arnold, offers a glimpse at how Machine Inc. represents the US manufacturing future – sophisticated manufacturing with robotic and automated solutions that make manufacturing more efficient and competitive against US based and offshore companies.

To listen to the episode, click the “play” button below:

As the U.S. economy has been improving, it’s gotten some unexpected help. After decades of job cuts, manufacturing firms have been creating jobs, many of them well-paying jobs. One especially bright spot is a new generation of high-tech manufacturers. The NPR Interview on lean manufacturing takes a look ahead at whether this recovery is built to last.

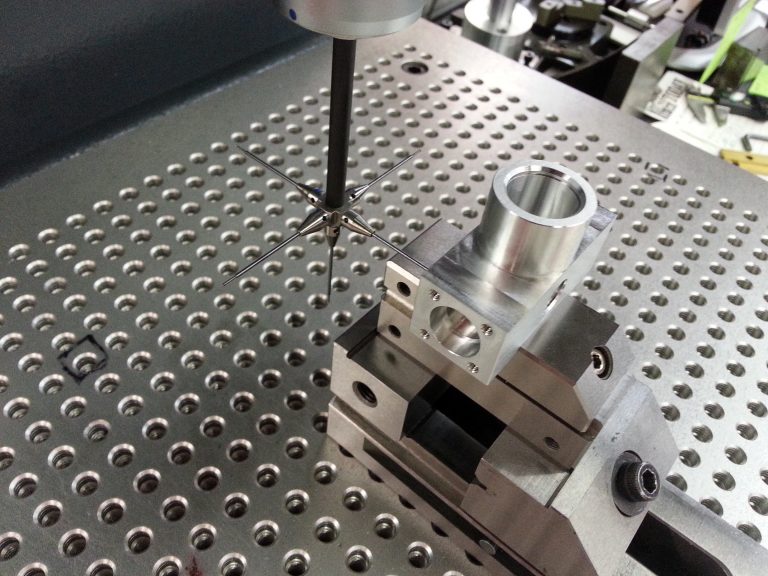

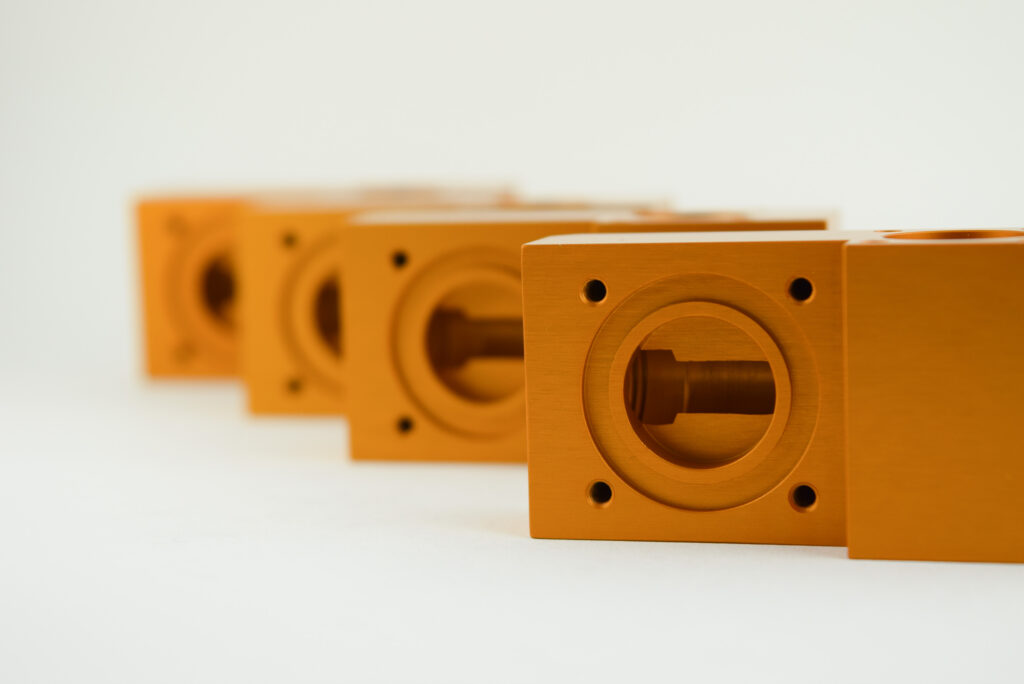

At a factory called Machine Inc. in Stoughton, Massachusetts, a hulking computer-controlled milling machine is cutting down a block of aluminum. It’s shaping it into an intricate aerospace component.

Richard Mileika is the company’s founder explains that an aluminum block goes in and finishes up as a completed manifold. It channels oxygen for delivery of oxygen on an aircraft.

The thing you notice right away here there are more machines and robotic arms working away on the factory floor than people. And that’s a big part of why this company can exist. To stay competitive with cheaper labor abroad, U.S. manufacturing has gotten more productive. That means more stuff with fewer workers. Actually at lunch and overnight, there are no people at all on the floor, just these machines doing the work.

For Machine Inc. that is our weapon for being competitive, whether it’s local competitors or global, being flexible and being productive. We see growth over the next year. We end up getting opportunities because of other competitors that just aren’t keeping up.

Richard Mileika, President of Machine Inc.

But even as lean and mean as this operation is, Machine Inc. has been buying more machines and hiring more workers. The desire is to hire more people, especially if we could find workers with the skills to run this equipment. They’re actually in short supply.

For more on how we can provide the CNC machining for your precision component needs, don’t hesitate to contact us to communicate with one of our experts.

Learn more about…