Quality / Certifications

Customers like you depend on us for precision machining quality certifications. Therefore, we maintain several governmental and industry accreditations.

click to expand:

AS9100/D

Quality Management System - Requirements for Aviation, Space, and Defense Organizations.

This International Standard specifies requirements for a quality management system for our organization to demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements, and aims to enhance customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements.

ISO 9001:2015

Quality Management System - Requirements

ISO 9001 is a globally recognized standard for quality management. It helps our organization to improve our performance, meet customer expectations and demonstrate our commitment to quality. Its requirements define how we establish, implement, maintain, and continually improve a quality management system (QMS).

FAA-PMA

Federal Aviation Administration - Parts Manufacturer Approval

A PMA is a combined design and production approval for modification and replacement articles. It allows a manufacturer to produce and sell these articles for installation on type certificated products. Federal Aviation Administration Orders 8110.42 and 8120.22 prescribe the approval procedures for FAA personnel and guides applicants in the approval process.

CAGE CODE

Commercial and Government Entity code - 7WG78

This code is a unique identifier assigned by the Defense Logistics Agency to suppliers to various government or defense agencies, as well as to government agencies themselves and also various organizations. CAGE codes provide a standardized method of identifying a given facility at a specific location.

D-U-N-S

Data Universal Numbering System - 618951008

The Dun & Bradstreet D-U-N-S Number is a unique nine-digit identifier for businesses that is associated with a business’s Live Business Identity which may help evaluate potential partners, seek new contracts, apply for loans, and so much more.

ITAR

International Traffic in Arms Regulations - Registrant code M49881

The Office of Defense Trade Controls Compliance (DTCC) registers manufacturers who engage in the United States in the business of manufacturing defense articles. We must keep the registration current pursuant to the Arms Export Control Act (AECA) and the International Traffic in Arms Regulations (ITAR). A registration is current if the registration is unexpired and has accurate and up-to-date information.

JCP

Joint Certification Program - Certification 0089635

The Joint Certification Program was established in 1985 to allow United States (U.S.)/Canadian contractors to apply for access to Department of Defense/Department of National Defence (DOD/DND) unclassified export controlled technical data/critical technology on an equally favorable basis.

SAM.GOV

System for Award Management - UEID PJVNAB7FUMN8

This is the official website of the U.S. Government where contractors register to do business with the U.S. Government. A Unique Entity ID is issued to prime contractors, organizations or individuals desiring to do business with the government.

Quality Policy

Machine Inc. will achieve customer satisfaction by:

Meeting customer requirements

Achieving on time deliveries goals

Creating consistent quality products

Having continuous improvement

Investing in technology, equipment & our employees

Needing to maintain customer satisfaction

Employing lean practices

Richard Mileika, President

What does a Quality Management System mean to us?

Tenets

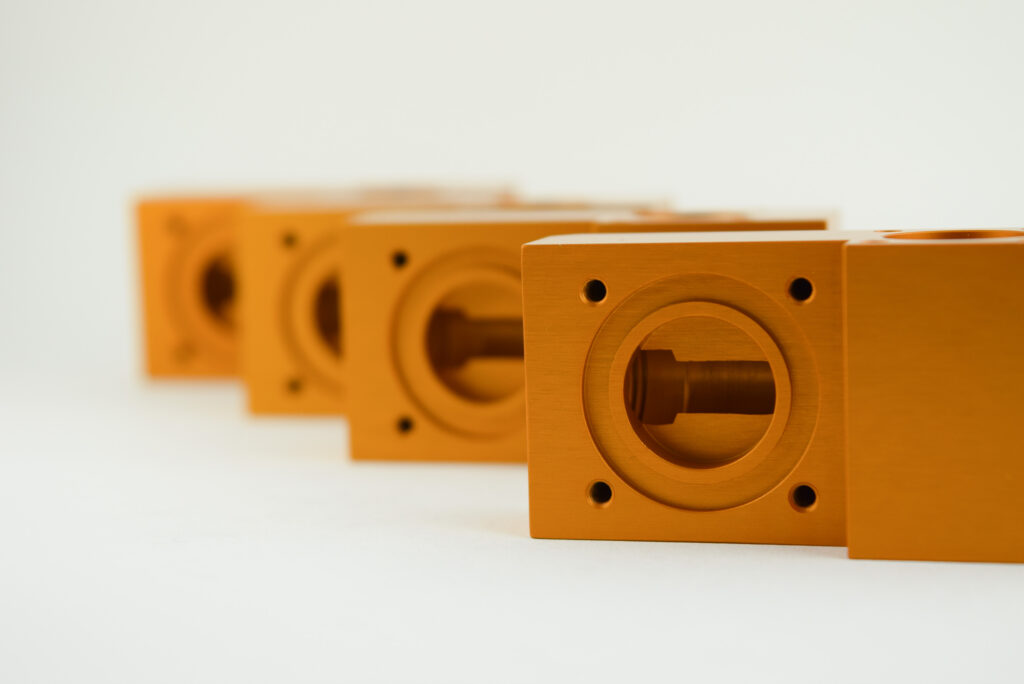

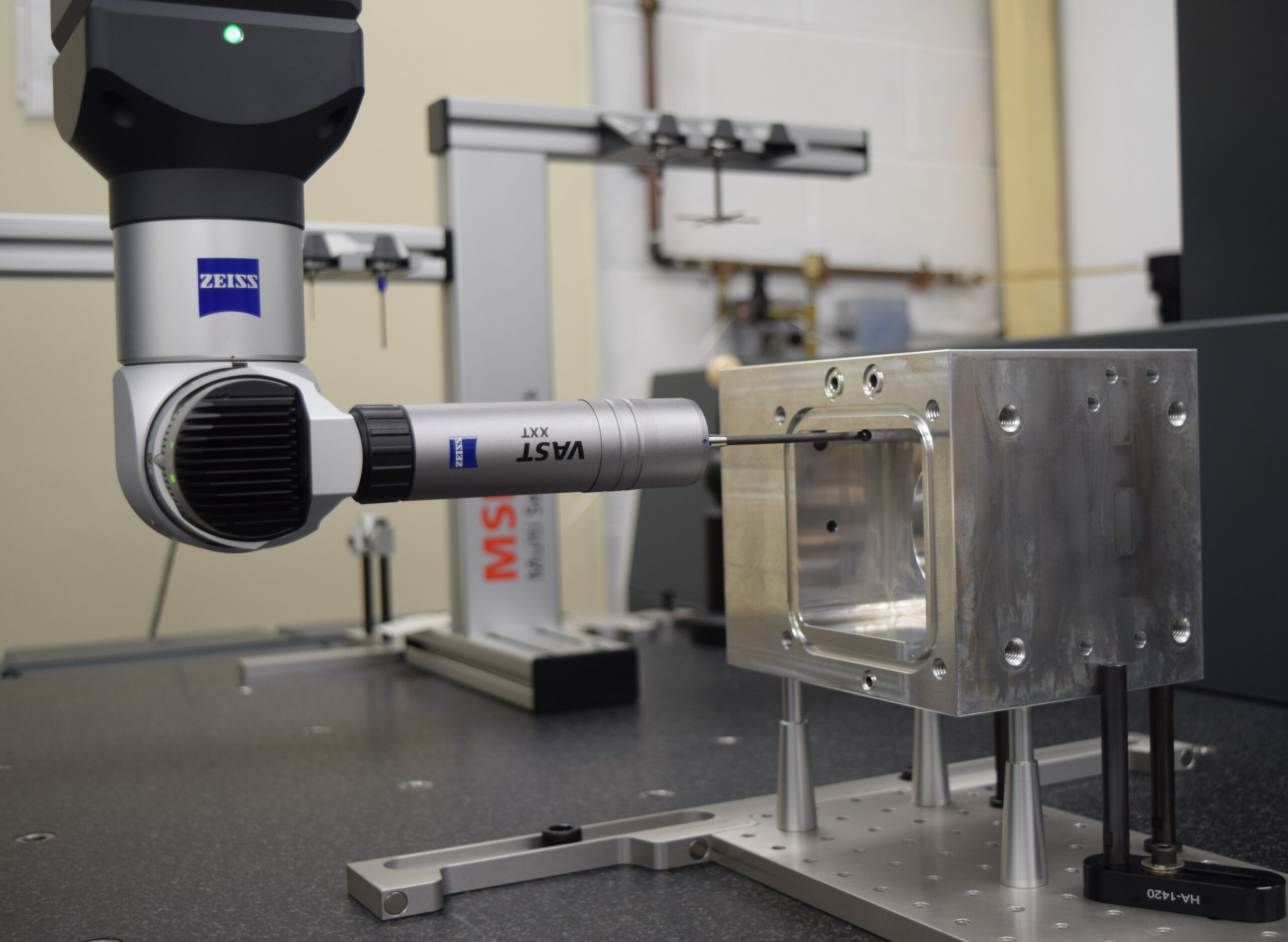

- Continuous Improvement: We have implemented numerous controls to prevent process errors that lead to rejects, allowing us to consistently deliver high quality machined parts.

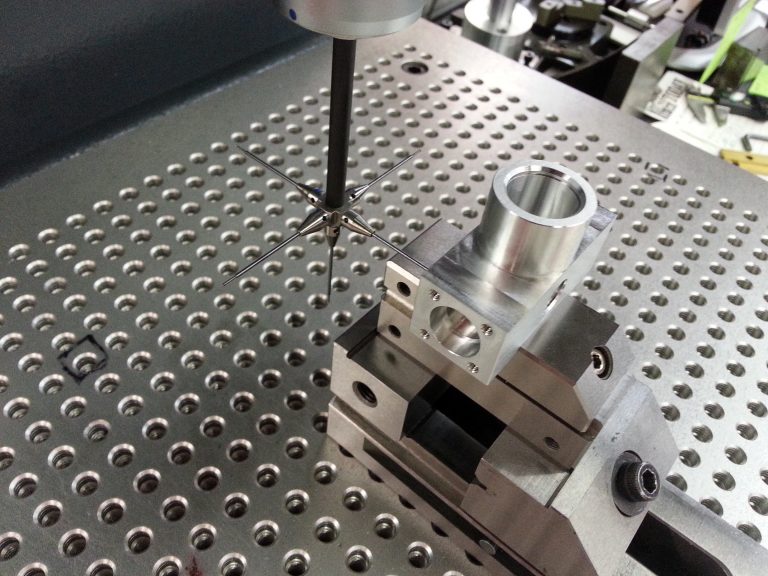

- In-process Quality Controls: Reduce unwanted variation resulting in less waste, scrap and reworks all contributing to the bottom line and reducing cost to our customers for precision machining quality certifications.

- Informational Pipeline: Actionable information to personnel, allowing them to detect, correct, and minimize process variation in real time.

- Customer Satisfaction: Strict attention to our machining processes assure consistent, high-quality parts, minimize rejects and enables us to provide comprehensive quality reports to our customers.

- Meet regulatory requirements through documentation control: Comprehensive documentation enables audit-ability across our processes, thereafter enables us to cost-effectively meet ISO, FAA, FDA and USDA requirements.

Benefits

- Minimize variation

- Prevent defects

- Reduce scrap, waste, rework

- Improve manufacturing yield

- Empower personnel with actionable intelligence

- Promote Lean Manufacturing

Our customers depend on us for precision machining quality certifications. For that reason, having AS9100 and ISO9001 Certification, plus our FAA-PMA approval, we strictly adhere to our quality system. In this situation, the good manufacturing practices that outline the aspects of production and testing can greatly impact the quality of machined parts. Although there are a number of them, our guidelines follow a few basic principles.

- Machining processes are clearly defined and controlled. All critical processes are validated to ensure consistency and compliance with specifications.

- Machining processes are controlled, and any changes to the process are evaluated and documented.

- Instructions and procedures are written in clear and unambiguous language.

- Operators are trained to carry out and document procedures.

- Records are made, manually or by instruments during machining that demonstrate that all the steps required by the defined procedures and instructions were taken and documented.

- Records of a machined part that enable the complete history of a batch to be traced are retained in a comprehensible and accessible form.

View our ISO/AS certification document here:

View our Aerospace Supplier Quality Requirements here:

View our Conflict-Free Minerals Policy document here:

Learn more about…