CNC Turning, Multi-Axis

With constantly improving technology and a keen eye on staying within budget, CNC machining in our economy has never been more competitive. But with industry leading capabilities, lean manufacturing, and concurrent engineering, Machine Incorporated has optimized multi-axis turning services to offer a level of comprehensive quality that’s a step above the rest.

Serving a growing number of industries

Over the years, Machine Incorporated has served a growing number of industries with CNC multi-axis turning. Some of these industries and applications include:

Industries

- Aerospace

- Defense

- Diagnostic equipment

- Fluid Control

- Heavy equipment

- Medical instruments

- Motion Control

- Power

- Telecommunications

- And more

CNC Turning Capabilities

- Manifolds

- Nozzles

- Valves/Valve components

- Pumps/Pump components

- Sleeves, Covers, Housings

- Couplings

- And more

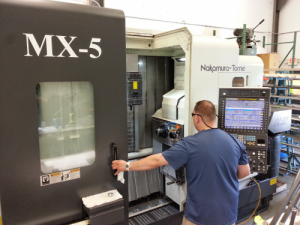

CNC multi-axis turning at Machine Incorporated utilizes state of the art equipment combined with years of industry experience to deliver better multi-axis turning faster and at a lower cost to our customers. In our effort to deliver higher levels of quality, productivity, and efficiency, we take advantage of twin spindles, twelve station turrets, multiple live tools, and continuous operation turning centers.

CNC multi-axis turning at Machine Incorporated utilizes state of the art equipment combined with years of industry experience to deliver better multi-axis turning faster and at a lower cost to our customers. In our effort to deliver higher levels of quality, productivity, and efficiency, we take advantage of twin spindles, twelve station turrets, multiple live tools, and continuous operation turning centers.

From the earliest stages of your project, our technicians at Machine Incorporated can offer their expertise to ensure your multi-axis turned parts are precisely what you need. This can include everything from design assistance to ensure low-cost manufacturability, material selection, prototyping, final assembly, and more. Additional multi-axis turning capabilities include:

- Autonomous, full-time quality control that’s focused solely on inspection

- Close tolerances in “tenths” range

- CNC gundrilling for deep holes

- Multi-axis turning focused on manufacturability

- Multiple live tools to enable part finishing on one machine

- Advanced quality control using statistical process controls (SPS)

- Full-service prototype development

- State of the art twin spindles to work on two sides of a part simultaneously

- Universal support for CAD and Solids Files

- Up to 2.5” diameter bar capacity

- And more